freetown

Electrical

- Mar 1, 2024

- 22

Hi all,

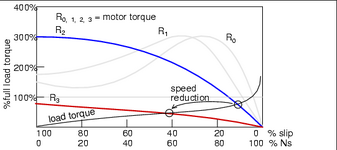

A slip-ring induction motor of 2700kW and 165A (stator) 990rpm, 1340V and 1250A (rotor). When we start the motor with no mechanical load (uncoupled motor so motor turns alone) we have 40A current and it's normal but what about the speed in this case, should we have a lower speed when make the test of motor turns alone?

We use liquid resistance starter to start the motor. This is because using a tool that monitoring device measures the rotor currents (and other parameters), it says low current and i assume it's normal and also low speed

Thank you.

A slip-ring induction motor of 2700kW and 165A (stator) 990rpm, 1340V and 1250A (rotor). When we start the motor with no mechanical load (uncoupled motor so motor turns alone) we have 40A current and it's normal but what about the speed in this case, should we have a lower speed when make the test of motor turns alone?

We use liquid resistance starter to start the motor. This is because using a tool that monitoring device measures the rotor currents (and other parameters), it says low current and i assume it's normal and also low speed

Thank you.