medeek

Structural

- Mar 16, 2013

- 1,104

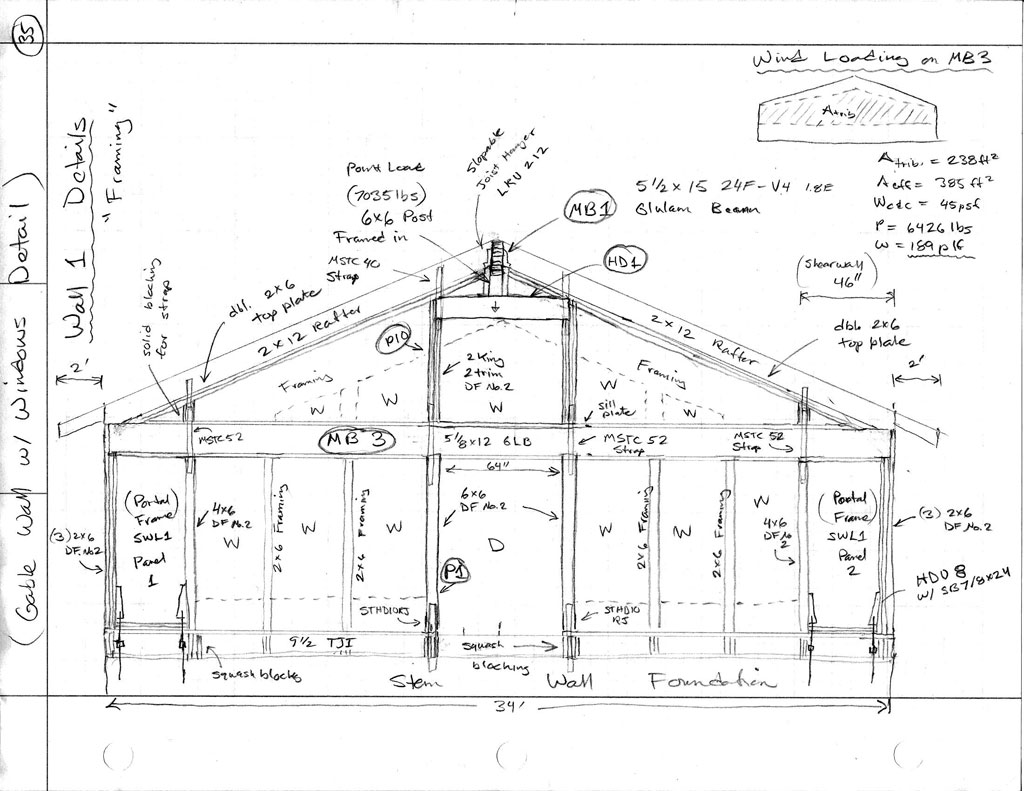

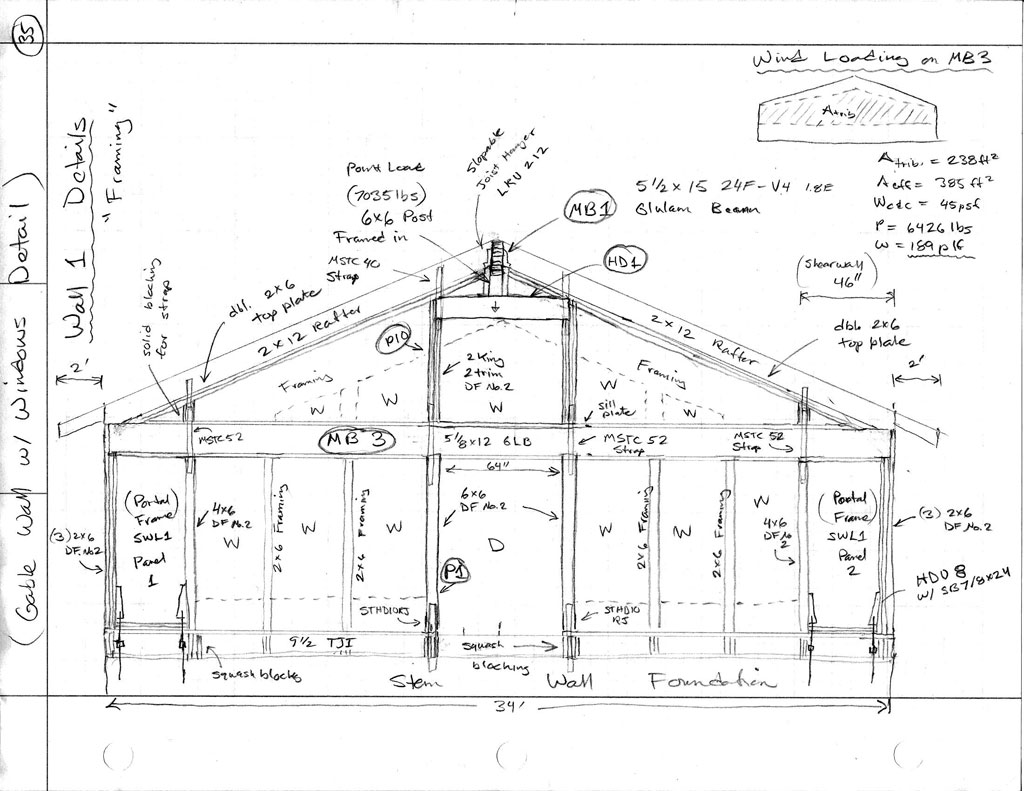

I've got a wall of windows on a gable end with possibly two methods of framing it (so far). Can anyone tell me what is wrong with the first picture? Note that 22 ft. of roof is tributary to to the glulam beam at the ridge (actually only half of that 11 ft is tributary to the gable wall). The load is the S + D, the dead load is approximately 50% of the total load.