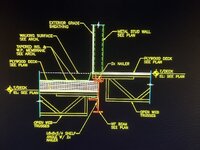

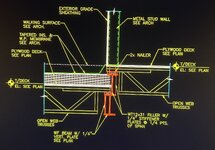

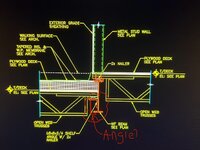

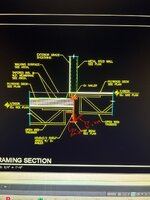

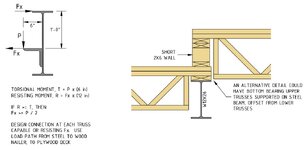

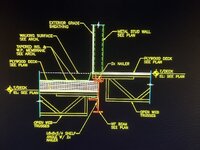

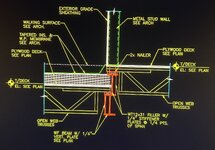

I’m working on two details along the same column line where there is a 12” step in the framing from inside to outside. I’m using a W21x44 in the first one and framing the exterior wood trusses into the side. For the 2nd detail, I’m using a W12x26 with a WT12x31 because the beam extends past the step so the beam needs to be lower, but the WT is needed for a portion of the span just to pick up the interior wood trusses on the right side of the detail.

I have the vertical 1/4” plate in the second detail to create a tube section with the beam flanges and the web because I think there is a torsional issue.

1) do you agree that there is a torsional issue with that detail?

2) does the first detail also have a torsional issue with the lower trusses framing into the side? Could I resolve it with an angle that gets welded to the angle supporting the trusses then to the bottom of the beam?

I have the vertical 1/4” plate in the second detail to create a tube section with the beam flanges and the web because I think there is a torsional issue.

1) do you agree that there is a torsional issue with that detail?

2) does the first detail also have a torsional issue with the lower trusses framing into the side? Could I resolve it with an angle that gets welded to the angle supporting the trusses then to the bottom of the beam?