Hello all,

we have a burner which use a napha for fuel and it have combustion air nozzle in burner.

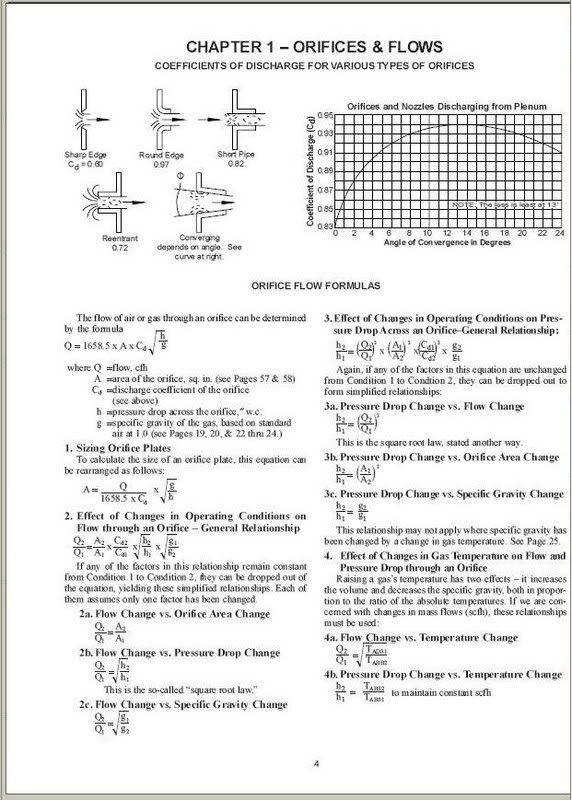

Combustion air flow 380 m3/min @ ATM

Combustion air fan discharge pressure : 500 mmAQ

Combustion air nozzel area : 120mm X 25mm

I would like to know what max. volume can go through that nozzle?

because we have enough fan capacity, but we can not increase to that air flow. so now we think it bottleneck is combustion air nozzel.

please can you calculate Max. vol. flow in this nozzle.

thank you

we have a burner which use a napha for fuel and it have combustion air nozzle in burner.

Combustion air flow 380 m3/min @ ATM

Combustion air fan discharge pressure : 500 mmAQ

Combustion air nozzel area : 120mm X 25mm

I would like to know what max. volume can go through that nozzle?

because we have enough fan capacity, but we can not increase to that air flow. so now we think it bottleneck is combustion air nozzel.

please can you calculate Max. vol. flow in this nozzle.

thank you