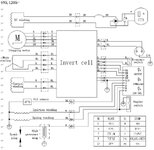

I’m looking for the wiring diagram for a petrol-driven electric generator. My web searches have yielded little. Possibly, someone on this forum has a source.

My little generator has lost its spark and consequently won’t start. It’s possible I can fix this by fumbling around. I’d rather locate some technical documentation if available – a technical manual. Which could be useful to have should other problems arise.

It’s an “Atomic” 700 watt generator. Model Ai700x. https://www.vektools.com.au/atomic-...-item-please-contact-us-for-alternatives.html Web searches for atomic tend to return the wrong kind of results.

The generator is probably Chinese and may sold by a variety of names. Here’s an example of a different generator that looks identical: https://www.amazon.com.au/GenTrax-Inverter-Generator-Portable-Camping/dp/B07NVKVT2D?th=1

If it’s the case these small generators are all the same except for their names, the manual to any small inverter generator may well suit my needs.

My little generator has lost its spark and consequently won’t start. It’s possible I can fix this by fumbling around. I’d rather locate some technical documentation if available – a technical manual. Which could be useful to have should other problems arise.

It’s an “Atomic” 700 watt generator. Model Ai700x. https://www.vektools.com.au/atomic-...-item-please-contact-us-for-alternatives.html Web searches for atomic tend to return the wrong kind of results.

The generator is probably Chinese and may sold by a variety of names. Here’s an example of a different generator that looks identical: https://www.amazon.com.au/GenTrax-Inverter-Generator-Portable-Camping/dp/B07NVKVT2D?th=1

If it’s the case these small generators are all the same except for their names, the manual to any small inverter generator may well suit my needs.