ewh

Aerospace

- Mar 28, 2003

- 6,139

Y14.5 lays out some basic drafting guidelines that are usually ignored (even by the standard itself) and somehow don't get the same attention as the GD&T aspect of the standard (understandable since the standards title is Dimensioning and Tolerancing, not Drafting).

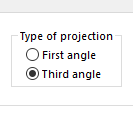

Drawings here are mostly peer reviewed as a check, but a new drawing review approval is now required and, while their GD&T understanding is good (due to the plentiful offering of training), there seems to be a problem familiarizing younger (and some older) engineers here with the basics of good drawing practices, from view projection issues to Y14.5 Fundamental Rules.

Are there any on-line or in-person (PNW) training classes covering general drafting rules in ASME (not just Y14.5)?

TIA!

Drawings here are mostly peer reviewed as a check, but a new drawing review approval is now required and, while their GD&T understanding is good (due to the plentiful offering of training), there seems to be a problem familiarizing younger (and some older) engineers here with the basics of good drawing practices, from view projection issues to Y14.5 Fundamental Rules.

Are there any on-line or in-person (PNW) training classes covering general drafting rules in ASME (not just Y14.5)?

TIA!