XL83NL

Mechanical

- Mar 3, 2011

- 3,107

Cant get my head around this, as I think Ive done it before under ASME, but cant recall how.

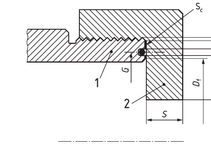

Im looking for some guidance in VIII-1 on a (large, 4") threaded end cap. The threads for the cap mate with the pressure shell. Below is a picture of the situation. Item 2 is the cap, with straight threads, that mates with a pressurized shell (item 1) having the same straight threads, on the outside.

My sutiation is slightly different (a.o. I have an insert between 1 and 2, holding the O-ring), but essentially works the same. This config isn't listed under UG-34. Appendix Y doesn't. I found a possibility under an EN standard for gas loaded accumulators, but Id like to stick with ASME all the way to keep things clear.

Any through if something similar is addressed somewhere in VIII-?

Im looking for some guidance in VIII-1 on a (large, 4") threaded end cap. The threads for the cap mate with the pressure shell. Below is a picture of the situation. Item 2 is the cap, with straight threads, that mates with a pressurized shell (item 1) having the same straight threads, on the outside.

My sutiation is slightly different (a.o. I have an insert between 1 and 2, holding the O-ring), but essentially works the same. This config isn't listed under UG-34. Appendix Y doesn't. I found a possibility under an EN standard for gas loaded accumulators, but Id like to stick with ASME all the way to keep things clear.

Any through if something similar is addressed somewhere in VIII-?