franhd

Mechanical

- Aug 13, 2023

- 10

Hi everyone,

I'm pretty sure I know the answer to this, but just want to double check here.

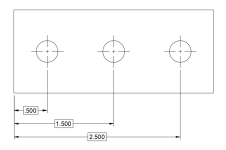

Take the example image above, and you're asked to measure true position of all three holes, with respect to datums A | B | C.

The first hole from left edge will have position measured with .500 as the target.

The next two holes, I would assume you use 1.500 and 2.500 as the target to calculate true position since datum C is the reference datum.

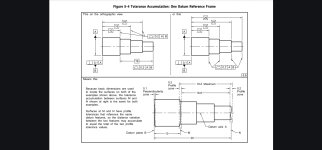

What I don't want to happen is inspectors stacking tolerances from hole to hole and for ex. calculate true position with 1.000 from the adjacent hole.

I don't see too many resources explaining this. Let me know if I'm correct about this or not.

Thanks!