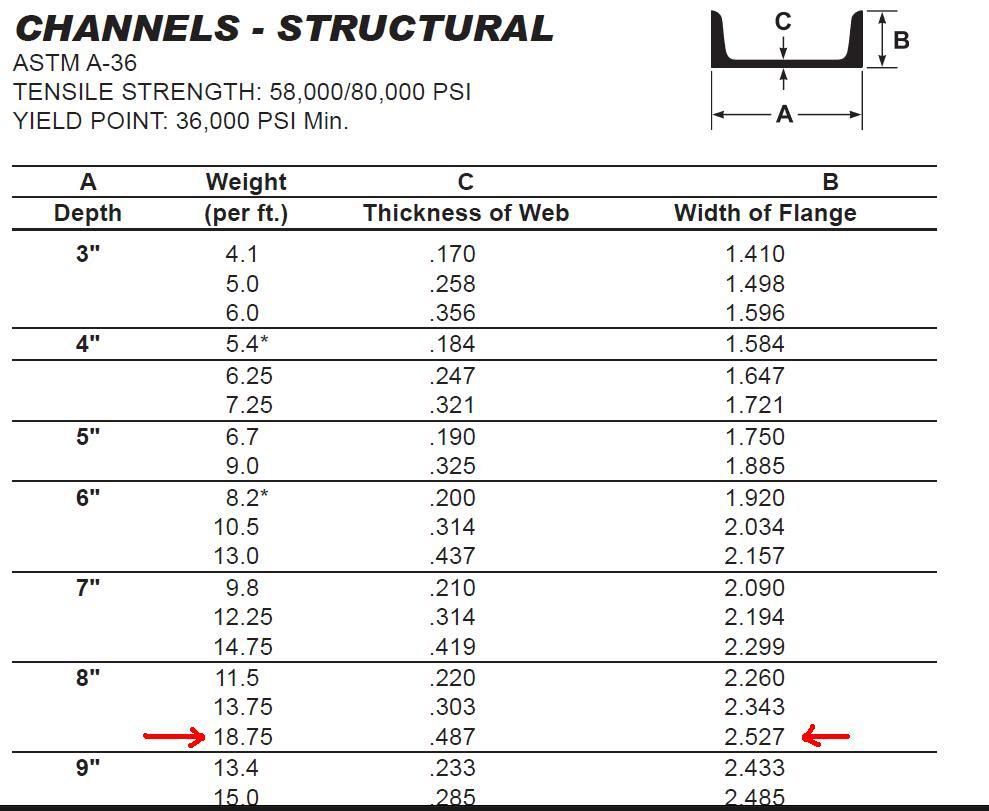

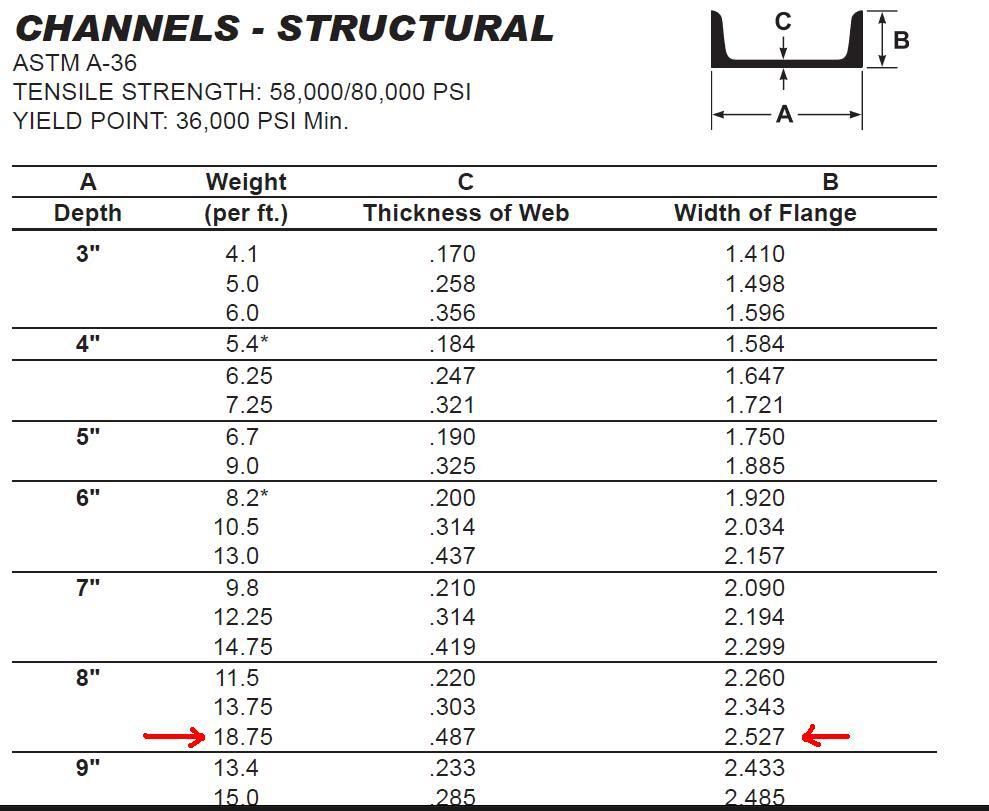

So i have a 'c' channel beam as shown here: The beam i used is marked with red

I assumed the whole beam to be of thickness C (.487") in this case.. found my moment of inertia to be Ixx=1.80621in^4

Here is my eulers formula

Fcr = (pi^2 x E x I)/L^2 I used english standard units which i think are correct but see if i am correct here:

E for astm a36= 200gpa = 29007547.54psi

I is my moment of inertia in inches^4 = 1.80621 (using the 8" beam with thickness of .487" and spars of 2.527")

Fcr = (3.14^2 x 2907547.54psi x 1.80621in^4 )/216"^2 = 11072.126 lbs before one beam buckles..

does this sound right or did i loose something in the units/math error?

As always thanks in advance and if you need ANY automotive engineering or performance advice feel free to email me as I am not on here that often.

I assumed the whole beam to be of thickness C (.487") in this case.. found my moment of inertia to be Ixx=1.80621in^4

Here is my eulers formula

Fcr = (pi^2 x E x I)/L^2 I used english standard units which i think are correct but see if i am correct here:

E for astm a36= 200gpa = 29007547.54psi

I is my moment of inertia in inches^4 = 1.80621 (using the 8" beam with thickness of .487" and spars of 2.527")

Fcr = (3.14^2 x 2907547.54psi x 1.80621in^4 )/216"^2 = 11072.126 lbs before one beam buckles..

does this sound right or did i loose something in the units/math error?

As always thanks in advance and if you need ANY automotive engineering or performance advice feel free to email me as I am not on here that often.