Martin.H

Structural

- May 19, 2021

- 40

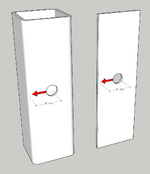

Should 'edge' distance reductions (i.e. EN 1993-1-8 Table 3.4 Ab and k1 factors) apply to an bolt in a SHS/RHS member, when loaded towards that members radiused edge (aka corner)?

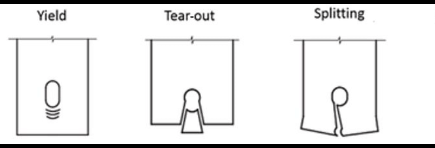

I put 'edge' in quotes as it's not a free edge subject to block tearing (as it continues around to the next face), but I can also imagine a bolt right next to a hollow sections edge radius won't perform as well as a bolt well set back from the edge radius when attempting to shear the bolt out the nearest side. I've not found any guidance on this.

I put 'edge' in quotes as it's not a free edge subject to block tearing (as it continues around to the next face), but I can also imagine a bolt right next to a hollow sections edge radius won't perform as well as a bolt well set back from the edge radius when attempting to shear the bolt out the nearest side. I've not found any guidance on this.