bugbus

Structural

- Aug 14, 2018

- 533

Are there any situations in which hand-tightened bolts (less than snug tight, basically loose) can be relied on for structural capacity?

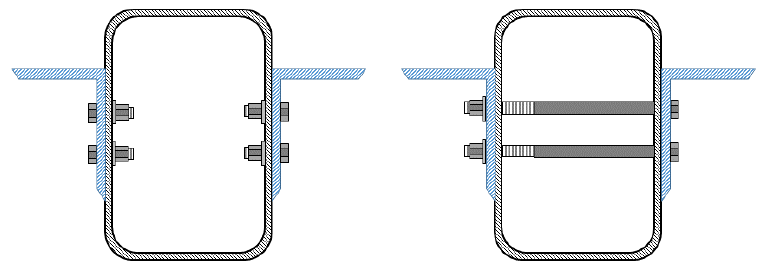

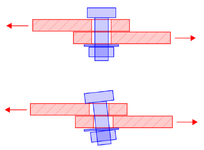

I am checking a steel-composite structure which is intended to be continuous for the future live loading. The beams are initially to be installed in a simply-supported arrangement, then a series of splice plates will be (loosely) installed, and finally a continuous concrete deck cast on top. The splice bolts would then be fully tensioned after the deck has been cast and cured, and the beams have taken up most of the deflection due to the wet concrete. The intention of installing the splice plates loosely is to prevent any unintended continuity of the girders until after the deck is cast and cured.

My question is whether the bolts can be relied on for structural capacity in this hand-tightened condition? We may end up needing to rely on them in the temporary case to provide restraint to the beams during construction.

Thanks in advance

I am checking a steel-composite structure which is intended to be continuous for the future live loading. The beams are initially to be installed in a simply-supported arrangement, then a series of splice plates will be (loosely) installed, and finally a continuous concrete deck cast on top. The splice bolts would then be fully tensioned after the deck has been cast and cured, and the beams have taken up most of the deflection due to the wet concrete. The intention of installing the splice plates loosely is to prevent any unintended continuity of the girders until after the deck is cast and cured.

My question is whether the bolts can be relied on for structural capacity in this hand-tightened condition? We may end up needing to rely on them in the temporary case to provide restraint to the beams during construction.

Thanks in advance

Last edited: