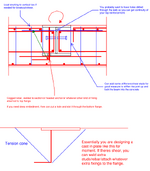

Has anyone here ever analyzed a steel I-Beam cast in concrete for breakout? Some ideas I have are to add nelson studs to the web of the beam, or add weldable rebar to the sides/bottom, but I have never actually seen any calcs or procedures for this. I've got some pretty high tensile loads to resolve. Just wondering if there are some "typical" details or simple details that have been developped that I could look into.

Top of concrete is top of top flange, equipment is then welded to the top flange.

Top of concrete is top of top flange, equipment is then welded to the top flange.