XR250

Structural

- Jan 30, 2013

- 5,956

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

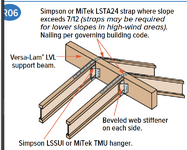

Face mount hangers most likely - LSSUI. I really hate using I-joists in a roof due to all those pesky web stiffeners top and bottom.Depends on how you're connection those I-joists. Top flange hangers? Probably not. Is this going to be exposed? Simpson makes a strap for this exact situation to brace the bottom of the beam. Well...not this exact situation...it's more for uplift on deep roof beams....but same basic idea.

Good reference.I downloaded this paper from a previous thread on the forum. There is a paragraph at the end that basically says if the beam is braced anywhere from mid-depth to the extreme compression fiber that it is likely effective. The farther away from the compression zone that the brace is the stiffer it needs to be.