Lutfi

Structural

- Oct 20, 2002

- 1,036

It has been a long while since I have been in this forum. Hello everyone.

I want to pick everyone’s brain here.

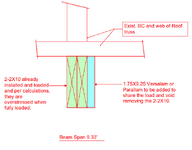

I have been called, of course after the fact, to evaluate a situation where a contractor has already installed a beam, 9.33’ span made up from SYP number 2. The beam is supporting 5 roof trusses, and it is already loaded. See the attached simple and NTS section.

The contractor and the owner are not for removing and replacing the already installed 2-2X10.

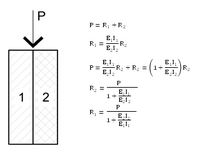

My approach is to add an Microlam on one side or both sides of the beam. I know the conservative approach is to assume the Microlam will carry all the entire load. This would be the easy way out. However, being an engineer, I want a logical way that I can use with the assumption that both beams are sharing the load proportionally based on their stiffness. So, I can apply prorated load to each one.

My question is, how to come up with a logical prorating percentage?

Please no comment to chastise the contactor nor the owner.

I want to pick everyone’s brain here.

I have been called, of course after the fact, to evaluate a situation where a contractor has already installed a beam, 9.33’ span made up from SYP number 2. The beam is supporting 5 roof trusses, and it is already loaded. See the attached simple and NTS section.

The contractor and the owner are not for removing and replacing the already installed 2-2X10.

My approach is to add an Microlam on one side or both sides of the beam. I know the conservative approach is to assume the Microlam will carry all the entire load. This would be the easy way out. However, being an engineer, I want a logical way that I can use with the assumption that both beams are sharing the load proportionally based on their stiffness. So, I can apply prorated load to each one.

My question is, how to come up with a logical prorating percentage?

Please no comment to chastise the contactor nor the owner.