Hello everyone,

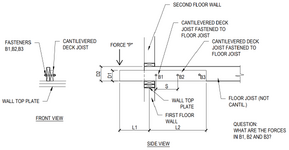

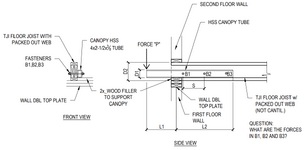

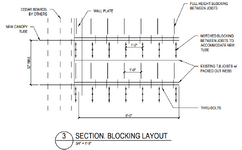

Every once in a while I need to design a deck with joists fastened to the side of floor framing. See attached. I am wondering what your approach would be to come up with shear forces in bolts B1, B2, and B3.

See attached and thank you for your input.

Every once in a while I need to design a deck with joists fastened to the side of floor framing. See attached. I am wondering what your approach would be to come up with shear forces in bolts B1, B2, and B3.

See attached and thank you for your input.