sleepdrifter

Mechanical

- Mar 21, 2025

- 10

Have a tight tolerance I need to hold on the ID and OD of a part, but it's only over a 1/2" section. What's the cleanest and most proper way to notate this?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

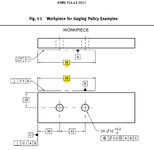

Ok so if I go ahead and use a chain line, how can I best specify the rest of the diameter to have a looser tolerance? Just show that in another view? Attached is what I currently have (I've increased my limited length to 0.875):See "Limited Length or Area Indication" in ASME Y14.5.

The above example if the mating part lays within that basic dimension it is functional. But guaranty the entire surface will be flat. And toLimited length or area dimensions are a lot like datum target area dimensions. You don't control their variation on the part drawing that uses them, but that's also why you should specify them as basic ("theoretically exact") - you assume that they are exact and someone's job is to make sure that their practical application is accurate enough.

View attachment 7406For dimensions to holes it works perfect , and is a great way of dimensioning. No argument there, and concurr. Buy dimensioning diameter I feel is over kill.

good ideaAppreciate all of your feedback. I agree that the 39 dia as well as the 36.4 dia shouldn't be basic.. their size really doesn't matter for my application. The only critical part is that shown in Detail D. The Chain line controlling the major dia can also have a pretty loose tolerance by intent to lax requirements on the major dia.

I'm going to be working directly with the machinist who will produce this part, so I'll take his feedback on how to dimension this better given my application.