I'm exploring the possibility of making a radiant floor heating system for a RV or van with a propane tankless water heater. I've been using a 12 liter per min. heater in a RV for years and am very happy with it. I just wonder how efficient it would be if I got a water pump and some pex tubing and made a closed system. The heater seems to be very efficient for my hot water so I just wonder if it would be worth while to make a heat system. I like the idea of having the heater outside where no fumes would get in and pump the hot water through the tubing. Any thoughts on how efficient it could be. I'm not at the point to do mathematical calculations just looking for a semi educated guess.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations TugboatEng on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

DIY radiant heat system

- Thread starter seayaker

- Start date

- Status

- Not open for further replies.

- Thread starter

- #21

Engineers with hobbies forum? I don't know where that is. I was about to close this thread when I got the add for diesel heaters. The photos are just examples, I'll probably try to find something in a scrap yard to use for an exchanger and pump set it up and see what happens. The heater does have some adjustments, if I can get it to run for 10-15 min. and see what kind of heat I get from the radiator I'd have a good idea if it could work or what I need to do.

LittleInch

Petroleum

Here https://www.eng-tips.com/forums/engineers-with-hobbies.1528/

The heat and the other things can all be calculated. Far better to design it right then test it.

The heat and the other things can all be calculated. Far better to design it right then test it.

LittleInch

Petroleum

Seayaker,

Not sure if you will get notification of this, but I've been thinking about this and see the information below which i think you need to use.

Heat load I don't think is going to more than 2-3kW for such a use and size of RV / trailer, even if it is not insulated, at least for one room. The issue with your 6l heate ris that I think this is about 16kW (~50-60 kBtu/hr). This is just far too big a duty and if you try and use it the burner will just be going on and off constantly. That is if it will even work which depends a lot on how the unit control temperature.

Many simple water heaters just work on or off, with temperature control affected by a control valve which just reduces or increases flow through the heater. More water flow - lower output temperature. This may be disguised as a nice dial on the front, but it is basically just a normal tap like valve which controls flow. Over temperature cut offs are there as a back up to stop the unit boiling water and exploding. Many just work on either a high pressure or a flow switch in order to fire up.

For a heater type system this doesn't work becasue the water coming back into the heater from your circuit is gradually warmer as the whole thing heats up.

So working out how the water heater control temperature is vital to making any system work and also whether it is a simple on/off burner arrangement like most water heaters are.

So to make this work you need the smallest water heater you can find and wir out how it starts and stops and control temperature, but this may simply not be posisble for a simple water heater. hence why some sort of boiler / furnace run by LPG is far better. Most of these will either modulate the heat input or work on a band of temperature so fire at say 55 C and turn off at say 65 or 70 C.

If you mount this lot outside you will need to use antifreeze of some sort which reduces the heat capacity of the water making all your problems a bit worse.

I do understand you're trying to do this very cheaply with things you have to hand or get get for little cost, but I really don't think your current design and sizing will work.

If you've got more information or ides, then let us know.

Not sure if you will get notification of this, but I've been thinking about this and see the information below which i think you need to use.

Heat load I don't think is going to more than 2-3kW for such a use and size of RV / trailer, even if it is not insulated, at least for one room. The issue with your 6l heate ris that I think this is about 16kW (~50-60 kBtu/hr). This is just far too big a duty and if you try and use it the burner will just be going on and off constantly. That is if it will even work which depends a lot on how the unit control temperature.

Many simple water heaters just work on or off, with temperature control affected by a control valve which just reduces or increases flow through the heater. More water flow - lower output temperature. This may be disguised as a nice dial on the front, but it is basically just a normal tap like valve which controls flow. Over temperature cut offs are there as a back up to stop the unit boiling water and exploding. Many just work on either a high pressure or a flow switch in order to fire up.

For a heater type system this doesn't work becasue the water coming back into the heater from your circuit is gradually warmer as the whole thing heats up.

So working out how the water heater control temperature is vital to making any system work and also whether it is a simple on/off burner arrangement like most water heaters are.

So to make this work you need the smallest water heater you can find and wir out how it starts and stops and control temperature, but this may simply not be posisble for a simple water heater. hence why some sort of boiler / furnace run by LPG is far better. Most of these will either modulate the heat input or work on a band of temperature so fire at say 55 C and turn off at say 65 or 70 C.

If you mount this lot outside you will need to use antifreeze of some sort which reduces the heat capacity of the water making all your problems a bit worse.

I do understand you're trying to do this very cheaply with things you have to hand or get get for little cost, but I really don't think your current design and sizing will work.

If you've got more information or ides, then let us know.

- Thread starter

- #24

- Thread starter

- #25

I'm thinking about converting an old RV oven to a heater for a van camper. The air intake would come from outside so when the door is shut it would be sealed. I would open the door and light it manually, so I would know if there was any gas in the box also have a gas detector and a flame sensor so the gas would shut off if it went out. This would be in the room like a wood stove a few feet of the floor. I have some computer fans that are very quiet I could use to blow air through the 3 tubes.

If you have any suggestions, or see any way to make it more safe and efficient please let me know.

If you have any suggestions, or see any way to make it more safe and efficient please let me know.

Last edited:

Sounds like recipe for potential disaster; there are already research that show that, at least for natural gas, many health risks from the burned and even the raw gas supply, and unless you have multi-redundant safety systems and interlocks, it's a high risk. The more complicated you have to make your system, the riskier it is.

LittleInch

Petroleum

So are you ducting the air in and burnt gas out? Have you tried this as the burners are probably not designed like that and may not burn the gas properly and you risk incomplete combustion unless the inlet and exhaust duct is really quite big and very short. You might want to locate it outside and forget about these ducts. Incomplete combustion causes sooting, CO (make sure you have a working CO monitor) and inefficiency.

You need to seal those holes quite well to avoid heat loss and gas entering the cabin.

Your tubes should be finned to increase heat transfer from the oven and if you have this inside do the same on the exhaust pipe then add a cage around it to avoid burning yourself on the exhaust pipe.

At least here you have some temperature control but you will burn a LOT of LPG as this is unlike to be more than 50% efficient.

Keep the oven the same as it was before as much as you can and think about putting it outside in a box and get insulated air ducts into the RV.

Or run a copper coil inside the oven and run water through it like you were planning before as this would be a much smaller hole into your RV.

Any details of the oven to see how much lower it could give you?

You need to seal those holes quite well to avoid heat loss and gas entering the cabin.

Your tubes should be finned to increase heat transfer from the oven and if you have this inside do the same on the exhaust pipe then add a cage around it to avoid burning yourself on the exhaust pipe.

At least here you have some temperature control but you will burn a LOT of LPG as this is unlike to be more than 50% efficient.

Keep the oven the same as it was before as much as you can and think about putting it outside in a box and get insulated air ducts into the RV.

Or run a copper coil inside the oven and run water through it like you were planning before as this would be a much smaller hole into your RV.

Any details of the oven to see how much lower it could give you?

- Thread starter

- #28

Seayaker,

Not sure if you will get notification of this, but I've been thinking about this and see the information below which i think you need to use.

Heat load I don't think is going to more than 2-3kW for such a use and size of RV / trailer, even if it is not insulated, at least for one room. The issue with your 6l heate ris that I think this is about 16kW (~50-60 kBtu/hr). This is just far too big a duty and if you try and use it the burner will just be going on and off constantly. That is if it will even work which depends a lot on how the unit control temperature.

Many simple water heaters just work on or off, with temperature control affected by a control valve which just reduces or increases flow through the heater. More water flow - lower output temperature. This may be disguised as a nice dial on the front, but it is basically just a normal tap like valve which controls flow. Over temperature cut offs are there as a back up to stop the unit boiling water and exploding. Many just work on either a high pressure or a flow switch in order to fire up.

For a heater type system this doesn't work becasue the water coming back into the heater from your circuit is gradually warmer as the whole thing heats up.

So working out how the water heater control temperature is vital to making any system work and also whether it is a simple on/off burner arrangement like most water heaters are.

So to make this work you need the smallest water heater you can find and wir out how it starts and stops and control temperature, but this may simply not be posisble for a simple water heater. hence why some sort of boiler / furnace run by LPG is far better. Most of these will either modulate the heat input or work on a band of temperature so fire at say 55 C and turn off at say 65 or 70 C.

If you mount this lot outside you will need to use antifreeze of some sort which reduces the heat capacity of the water making all your problems a bit worse.

I do understand you're trying to do this very cheaply with things you have to hand or get get for little cost, but I really don't think your current design and sizing will work.

If you've got more information or ides, then let us know.

I have considered these things, first I would definitely test it extensively outside before considering installing it. The oven is in my RV now, I disconnected it years ago and use an electric one. Many RV's use propane ovens, the only difference is that the box would be in the room to radiate the heat rather than contain it. The oven exhaust doesn't even go directly outside, it just vents to the top where the burners are and then all that supposably goes out the hood. This would go all the way up and out. The RV furnaces which are under the cabinets use a powerful fan to blow the heat out. They have to have a fan on start up to purge the chamber before they can light. If you think this would be about 50% efficient how efficient are those? Is there anything using LPG that would more efficient?So are you ducting the air in and burnt gas out? Have you tried this as the burners are probably not designed like that and may not burn the gas properly and you risk incomplete combustion unless the inlet and exhaust duct is really quite big and very short. You might want to locate it outside and forget about these ducts. Incomplete combustion causes sooting, CO (make sure you have a working CO monitor) and inefficiency.

You need to seal those holes quite well to avoid heat loss and gas entering the cabin.

Your tubes should be finned to increase heat transfer from the oven and if you have this inside do the same on the exhaust pipe then add a cage around it to avoid burning yourself on the exhaust pipe.

At least here you have some temperature control but you will burn a LOT of LPG as this is unlike to be more than 50% efficient.

Keep the oven the same as it was before as much as you can and think about putting it outside in a box and get insulated air ducts into the RV.

Or run a copper coil inside the oven and run water through it like you were planning before as this would be a much smaller hole into your RV.

Any details of the oven to see how much lower it could give you?

Last edited:

LittleInch

Petroleum

I looked up a few ovens and from what I can see these are about 30 to 35%efficient in terms of energy of the gas vs heat output of the oven.

In most cases the hot gas exhaust just goes into the cabin and creates water vapour and condensation. Still not sure where you're planning on venting the gas?

This type of oven looks like the burners heat the floor and maybe the back wall but it's not really an air heater.

Any burner which doesn't condense the burnt gas is not going to be better than 60 to 65% efficient.

Something like this looks better. https://www.vanconversionshop.co.uk/truma-varioheat-eco-28kw-heater-only---classic-control-829-p.asp

Or this https://www.jacksonsleisure.com/car...lGbhT9zcMwTHqeeCElwvJshqjqwwm1Roc1G4Cl_sZsCgn

I get you're trying to do this as a DIY fix, but this could burn you or your RV down if you get it wrong and burn huge amounts of LPG for not much heat output.

In most cases the hot gas exhaust just goes into the cabin and creates water vapour and condensation. Still not sure where you're planning on venting the gas?

This type of oven looks like the burners heat the floor and maybe the back wall but it's not really an air heater.

Any burner which doesn't condense the burnt gas is not going to be better than 60 to 65% efficient.

Something like this looks better. https://www.vanconversionshop.co.uk/truma-varioheat-eco-28kw-heater-only---classic-control-829-p.asp

Or this https://www.jacksonsleisure.com/car...lGbhT9zcMwTHqeeCElwvJshqjqwwm1Roc1G4Cl_sZsCgn

I get you're trying to do this as a DIY fix, but this could burn you or your RV down if you get it wrong and burn huge amounts of LPG for not much heat output.

Last edited:

- Thread starter

- #30

I thought it is pretty clear in post #25 that the exhaust goes out the roof, it's just like the wood stove I've been using for 10 yrs. It's sealed, gets air from outside and smoke goes out the chimney, exactly the same only different fuel. I've looked at the type in your link, it's similar to this one

or an RV furnace. (not at all what I want) Nobody talks about how much noise the fan makes or how much power it uses. I don't even need a fan for the one I build. Maybe I'm missing something but I don't see how any of those other heaters could be as efficient. My question is weather there would be any advantage to have the tubes just have the burner close to the top.

LittleInch

Petroleum

You did say that, but then I got a bit confused in post #28 when you said "The oven exhaust doesn't even go directly outside,".

Anyway a picture tells a thousand stories.

The issue I see is one of heat exchanger and heat output.

The furnace thing can be outside the RV, but it is optimised in terms of heat exchanger size, burner controls etc to maximise efficiency to heat air to about 60 or 70C being blown out of the air duct. An oven is designed to heat up fairly rapidly to 200C plus, but with an essentially static air flow other than convection and very little new air being added. The heat exchanger surface is really quite small though and hence its efficiency in terms of what you want (hot air) is going to be low. You could increase it by adding an external mesh plate surround to the exhaust and allowing air to circulate around it whilst guarding against burning yourself.

So if you drill holes in the oven as shown - and you would need air input at the bottom - yes you will get some warm air drifting out of the oven, but it will either be too hot and things close by could melt or burn, or more likely you would just not get that much heat out of it, maybe a few hundred watts. One thing you do need to do regardless is block off that vent hole at the back of the oven which was used before to vent steam and cooking vapours up the vent. If you add a chimney you could either drag in warm up up the chimney or have flue gases entering the room.

If you're going to try this, my recommendation would be to remove the door and then blow in air using a couple of the bigger 12V computer cooling fans (very quiet) from the top surface. Also add in a layer of those lava rocks from a BBQ to increase surface area on the bottom surface. Set the thermostat to no more than 70 or 80C just in case. you can control heat by turning on or off a fan.

does that make sense?

Anyway a picture tells a thousand stories.

The issue I see is one of heat exchanger and heat output.

The furnace thing can be outside the RV, but it is optimised in terms of heat exchanger size, burner controls etc to maximise efficiency to heat air to about 60 or 70C being blown out of the air duct. An oven is designed to heat up fairly rapidly to 200C plus, but with an essentially static air flow other than convection and very little new air being added. The heat exchanger surface is really quite small though and hence its efficiency in terms of what you want (hot air) is going to be low. You could increase it by adding an external mesh plate surround to the exhaust and allowing air to circulate around it whilst guarding against burning yourself.

So if you drill holes in the oven as shown - and you would need air input at the bottom - yes you will get some warm air drifting out of the oven, but it will either be too hot and things close by could melt or burn, or more likely you would just not get that much heat out of it, maybe a few hundred watts. One thing you do need to do regardless is block off that vent hole at the back of the oven which was used before to vent steam and cooking vapours up the vent. If you add a chimney you could either drag in warm up up the chimney or have flue gases entering the room.

If you're going to try this, my recommendation would be to remove the door and then blow in air using a couple of the bigger 12V computer cooling fans (very quiet) from the top surface. Also add in a layer of those lava rocks from a BBQ to increase surface area on the bottom surface. Set the thermostat to no more than 70 or 80C just in case. you can control heat by turning on or off a fan.

does that make sense?

- Thread starter

- #32

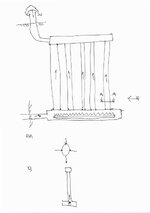

I can't seem to communicate what I'm doing, if we just forget everything else and focus on one thing The heat transfer from the flame of the burner to the air with the least amount of loss through the chimney. In this video is there any advantage to the channel running through the stove as apposed to just having the burner closer to the top with a fan outside? This is just an example don't read anything into it.

Last edited:

LittleInch

Petroleum

Essentially this is the same as your oven idea and the fan idea I talked about.

The tube just increases the heat transfer as the air being blown through keeps the tube temperature lower than it world be otherwise and blowing air increase the heat transfer coefficient between the hot metal surface and the air. It also increases the surface area of the hot metal

But you would get a similar effect of you blew air over the hot box. If you add fins to increase the surface area then heat transfer goes up.

Beware though that some of the temperatures that system gets to is very dangerous.

The tube just increases the heat transfer as the air being blown through keeps the tube temperature lower than it world be otherwise and blowing air increase the heat transfer coefficient between the hot metal surface and the air. It also increases the surface area of the hot metal

But you would get a similar effect of you blew air over the hot box. If you add fins to increase the surface area then heat transfer goes up.

Beware though that some of the temperatures that system gets to is very dangerous.

- Thread starter

- #36

Thanks,An aspect worth consideration is condensation from products of combustion, and, in particular, freezing of water vapor at the flue outlet.

I probably won't do this but would something like thisEssentially this is the same as your oven idea and the fan idea I talked about.

The tube just increases the heat transfer as the air being blown through keeps the tube temperature lower than it world be otherwise and blowing air increase the heat transfer coefficient between the hot metal surface and the air. It also increases the surface area of the hot metal

But you would get a similar effect of you blew air over the hot box. If you add fins to increase the surface area then heat transfer goes up.

Beware though that some of the temperatures that system gets to is very dangerous.

View attachment 3733

I was playing around with a few ideas, trying to get the air to circulate a bit without using a fan.Essentially this is the same as your oven idea and the fan idea I talked about.

The tube just increases the heat transfer as the air being blown through keeps the tube temperature lower than it world be otherwise and blowing air increase the heat transfer coefficient between the hot metal surface and the air. It also increases the surface area of the hot metal

But you would get a similar effect of you blew air over the hot box. If you add fins to increase the surface area then heat transfer goes up.

Beware though that some of the temperatures that system gets to is very dangerous.

Attachments

LittleInch

Petroleum

That increases the surface area so would be better, but not sure why you're so opposed to those 12V computer type fans which are very low noise and use very little power. Even a small forced air movement will double or triple your heat output. Simple convection either needs the box to be very high temperature like your fire / solid fuel burner to get a decent amount of heat or just doesn't emit much heat if the temperature is lower. High temperatures can be a problem in terms of burns or potential to cause a fire.

Because i went looking for data on another thread about cooling fans, Amazon are sending me detals on simlar ones like this https://www.amazon.co.uk/gp/product/B0B38KFVZX/ref=pe_4006351_1245123151_em_1p_0_lm?th=1

Noise is very low but fit those to the top of your oven, remove the door, block off the vent, add some lava rocks to increase surface area on the bottom plate and seen what happens. Just don't set oven temperature more than 60C or you'll melt the fans though.... what have you got to lose to see if it works? Or mount the fans remote from the oven, but close by and duct the air into it.

Because i went looking for data on another thread about cooling fans, Amazon are sending me detals on simlar ones like this https://www.amazon.co.uk/gp/product/B0B38KFVZX/ref=pe_4006351_1245123151_em_1p_0_lm?th=1

Noise is very low but fit those to the top of your oven, remove the door, block off the vent, add some lava rocks to increase surface area on the bottom plate and seen what happens. Just don't set oven temperature more than 60C or you'll melt the fans though.... what have you got to lose to see if it works? Or mount the fans remote from the oven, but close by and duct the air into it.

Last edited:

- Thread starter

- #38

remove the door, block off the vent? Do you not understand I'm building a new box and the combustion area is sealed from the room? The photo of the oven was just to show how it was vented. I may use some of the parts but the oven is history. I have fans with PWM variable speed control, they are as quiet as you can get, still I want to design the box to work best as possible without a fan. The reason I posted on this engineering forum is to get some advice about how to maximize the efficiency of the box while its still on paper. How best to get the most heat from the flame to the air in the room with as little heat loss through the chimney. The example in post #35 is similar to something I saw that would heat the air in the channel and create some air flow drawing cooler air from the bottom and exiting the top. I don't know how well it would work or if it would be worth it.

LittleInch

Petroleum

Ah, I thought you were planning to use the oven as it was redundant and actually still think that's a good plan as you're using recognised components.

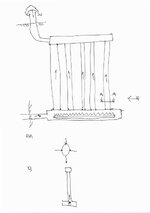

OK, if you're starting from scratch then I would build something tall and thin with a set of fins on it or a set of tubes with a collector manifold at the top to vent outside.

The longer you can make the tubes the better, but for a simple design your flue gas temp needs to be prob min 150C as you exit otherwise you'll get a load of condensation and corrosion. Probably need a bit of trial and error to see how many tubes and how long they can be versus amount of gas in. Start small.

The issue with the item in #36? is that there is actually very little surface area and hence the box and tube will just get very hot before the reach equilibrium with heat energy in equals heat energy out and the flue gas will be very hot which for an RV and for efficiency isn't good.

So I thought something like this?

OK, if you're starting from scratch then I would build something tall and thin with a set of fins on it or a set of tubes with a collector manifold at the top to vent outside.

The longer you can make the tubes the better, but for a simple design your flue gas temp needs to be prob min 150C as you exit otherwise you'll get a load of condensation and corrosion. Probably need a bit of trial and error to see how many tubes and how long they can be versus amount of gas in. Start small.

The issue with the item in #36? is that there is actually very little surface area and hence the box and tube will just get very hot before the reach equilibrium with heat energy in equals heat energy out and the flue gas will be very hot which for an RV and for efficiency isn't good.

So I thought something like this?

- Thread starter

- #40

- Status

- Not open for further replies.

Similar threads

- Question

- Replies

- 3

- Views

- 8K

- Replies

- 4

- Views

- 2K

- Locked

- Question

- Replies

- 5

- Views

- 4K

- Replies

- 1

- Views

- 2K

- Replies

- 0

- Views

- 741