IanVG

Mechanical

- Jan 21, 2022

- 76

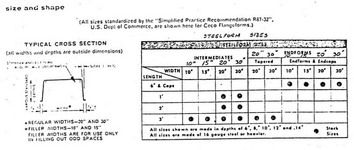

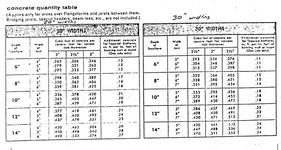

This is more or less a follow-up to my previous post (thread507-523158), but maybe understanding this point will help me understand the other point. On the one detail for typical joist construction for this project, I see that the first pan is variable dimension ('30", 20", 15" or 10" pans as required'). How was the dimension obtained? Is that only from the beam that it starts from or from anything else? It also seems that the bottom of the joist width for the first joist is variable, indicated by the note: "Where this dimension equals or exceeds typical joist width, reinforce as typical joist." Is there anyway for me to draft/model this system up without verifying every single dimension in field?