JStructsteel

Structural

- Aug 22, 2002

- 1,438

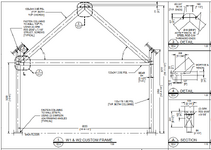

Got a ridge beam on a open deck that comes into end beams. Owner does not want a vertical post in the middle. he is ok with a tie at the bottom.

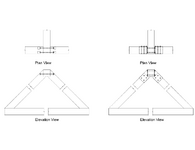

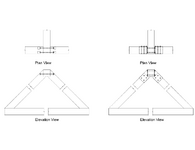

Playing around with details, I have come down to 2 options. Left is just tie bolts holding everything together, right is a saddle plate weldment for the connection. I know the best is the plates, but are there any other options? Maybe slots in the beams and a knife-flitch like plate hidden?

Load from ridge beam is about 6K, so not huge, but enough that I dont like the left one.

Thanks

Playing around with details, I have come down to 2 options. Left is just tie bolts holding everything together, right is a saddle plate weldment for the connection. I know the best is the plates, but are there any other options? Maybe slots in the beams and a knife-flitch like plate hidden?

Load from ridge beam is about 6K, so not huge, but enough that I dont like the left one.

Thanks