mechengineer

Mechanical

Dear Corrosion Experts,

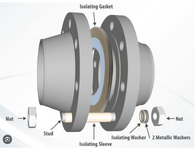

A pair of flanges connection:

one is SA-105 and

another is SA-182F316L.

Spiral Wound Gasket, wounding material of SS316L winding and graphite filter. Outer ring is CS and inner ring is SS316L.

Q1, Is there the galvanic corrosion between the CS flange and SS flange?

Q2, Is there the galvanic corrosion between the CS flange and SS winding material of the gasket?

Q3, If Q1 & Q2 are yes. Is there any suggestion or recommendation to resolve the issue (Galvanic Corrosion).

Thanks.

A pair of flanges connection:

one is SA-105 and

another is SA-182F316L.

Spiral Wound Gasket, wounding material of SS316L winding and graphite filter. Outer ring is CS and inner ring is SS316L.

Q1, Is there the galvanic corrosion between the CS flange and SS flange?

Q2, Is there the galvanic corrosion between the CS flange and SS winding material of the gasket?

Q3, If Q1 & Q2 are yes. Is there any suggestion or recommendation to resolve the issue (Galvanic Corrosion).

Thanks.