elinah34

Mechanical

- Aug 19, 2014

- 149

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

And fixing it on one side and letting it be hang is robust enough? I am not experienced in this field (gears etc.) so I am really asking.I don't know that I've ever seen one fixed rigidly on both ends. That thermal expansion needs to go somewhere. They are always fixed on the low speed end.

and can you tell me please why on the low speed side?I don't know that I've ever seen one fixed rigidly on both ends. That thermal expansion needs to go somewhere. They are always fixed on the low speed end.

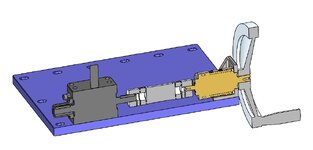

There is a clearance between the flange's hole and the gearbox cylindrical interface, so there will still be some flexibility and no over constraint. Something else might be a problem - if the brackets won't be enough perpendicular to the purple base plate there will be some internal undesirable strains.My concern is alignment. There is no way your two mounting points will be in perfect alignment. You are placing your gearbox in a bind.

Talk to the gearbox manufacturer and learn their recommended mounting method.

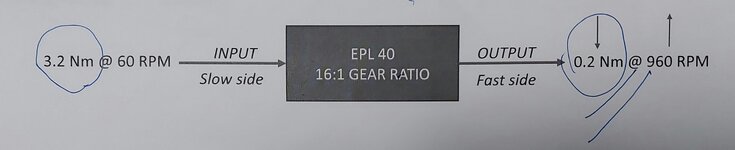

I am adding a picture that should give some additional information.That gearbox looks to have the same diameter input and output shafts - is it a low-ratio unit? The thermal expansion comment seems like good advice, however, since this appears to be hand cranked you may not have much heat generation.

You could probably get a lot of comments on alternate arrangements with a little more info on duty-cycle and required output torque and RPM at miter gearbox.

Hey and thanks for replying.Didn't connect that you were using this for a speed increaser. Most comments seem unchanged, although maximum forces will be at input end. I have made some hand cranked gizmos over the years and can comment that most operators are not too happy about needing to making more than a couple of revolutions of the wheel. You may want to put a tapped hole in the end of the input shaft and then put a keeper plate and screw in after installing handwheel in order to prevent the handwheel from walking off the end of the shaft.

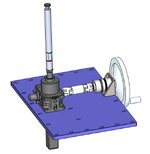

Here is your sketch for easier viewing -

View attachment 3551

Hey, I took your advice and talked to the application engineer.I say again:

"Talk to the gearbox manufacturer and learn their recommended mounting method."

I do not understand the hesitance of today's young engineers to pick up the phone and talk to a live person at a manufacturer's office. They have Application Engineers there. Those guys have ONE JOB - to help you successfully use their product. Ask them for help and guidance!

Engineering forums are helpful, but they are NOT a substitute for the innate, detailed knowledge of a specific product that one gets from a manufacturer's Application Engineer.

What do you mean by "keeper plate"?

I thought about locking the handwheel axially by a wide washer and a screw that will connect the input shaft end.

Doesn't look like it to me.OP

Does the bracket have a bearing.