XR250

Structural

- Jan 30, 2013

- 5,858

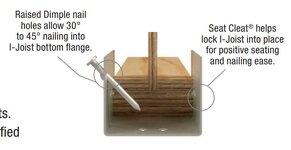

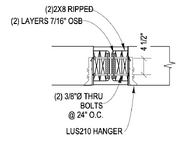

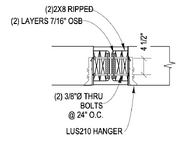

W8x67 flush beam w/ 2x10 joists on each side. This is how I showed the beam being packed out....

This is what I got.. Basically, they did not put the OSB in and just cranked the (2)2x8 into the kern of the beam so it is sitting about 3/8" inside the edge of the flange...

Now the hangers are not plumb and are bent. Not sure how to put a number to this. I realize the lower nails are missing but I am not even close to the hanger capacity. I'd like GC to take it down and do the padding correctly if not adding a bit thicker so it sits 1/4" proud of the beam as this will give them the opportunity to clean up the joist cuts. He will be upset to say the least. The entire installation is not great. I mean it is only an 1800 lb beam x 25 ft. long.

This is what I got.. Basically, they did not put the OSB in and just cranked the (2)2x8 into the kern of the beam so it is sitting about 3/8" inside the edge of the flange...

Now the hangers are not plumb and are bent. Not sure how to put a number to this. I realize the lower nails are missing but I am not even close to the hanger capacity. I'd like GC to take it down and do the padding correctly if not adding a bit thicker so it sits 1/4" proud of the beam as this will give them the opportunity to clean up the joist cuts. He will be upset to say the least. The entire installation is not great. I mean it is only an 1800 lb beam x 25 ft. long.

Last edited: