medeek

Structural

- Mar 16, 2013

- 1,104

I'm feeling pretty comfortable with conventionally framed structures as of late and most of my residential work falls with typical parameters that I've dealt with on similar projects.

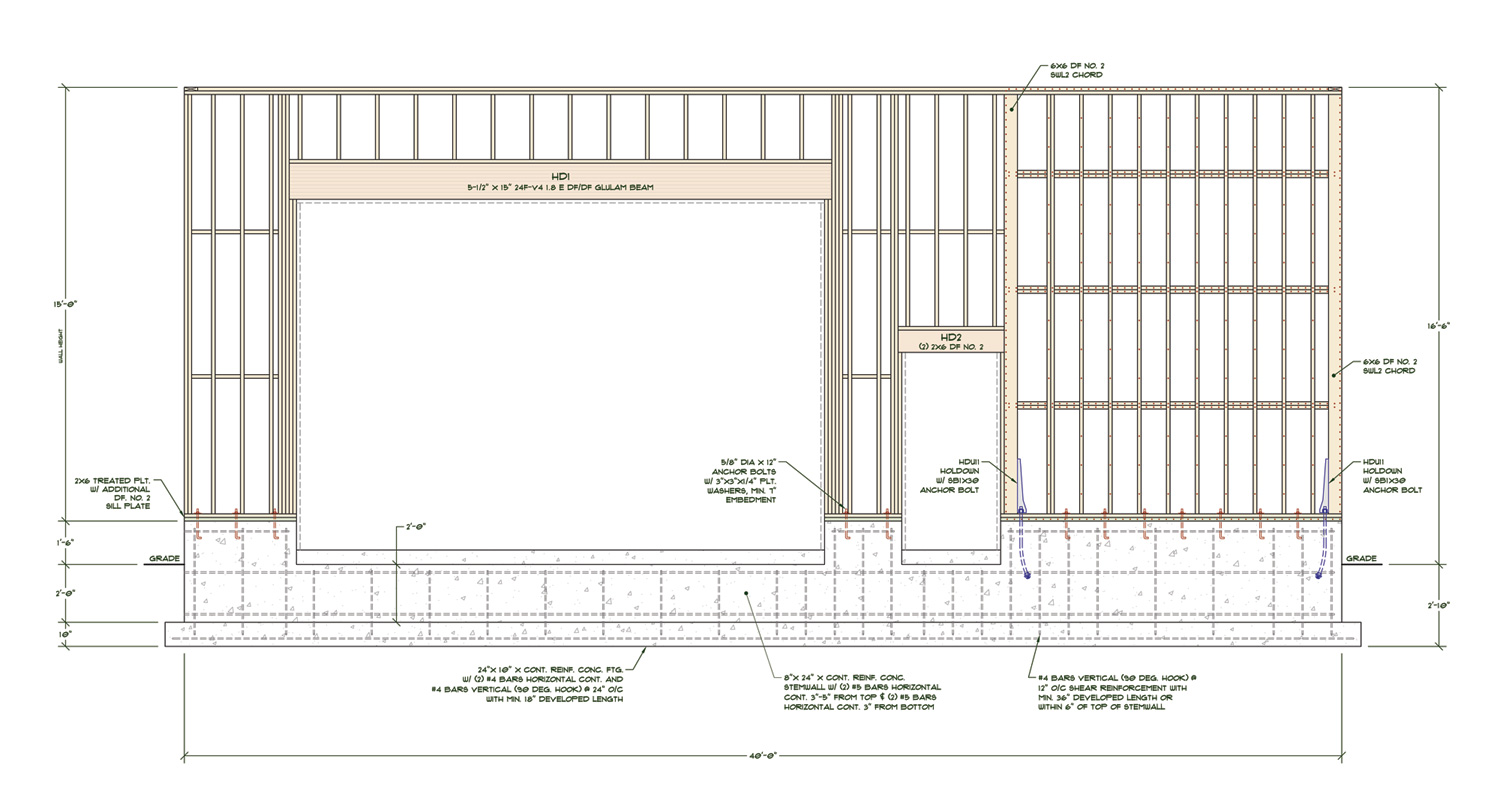

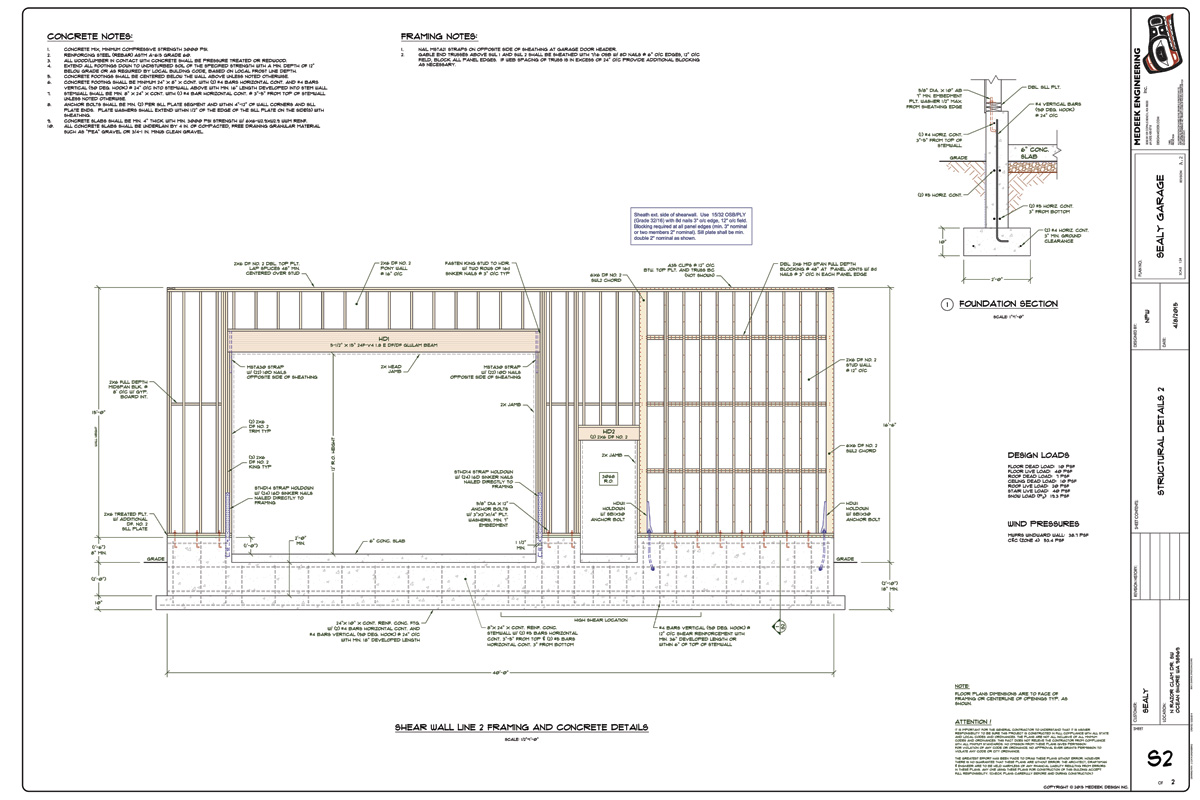

Today a large garage landed on my desk, conventional light wood frame construction. The only thing that really jumps out at me is the size of this structure. 40'x60' rectangle with 40' trusses on 15' high 2x6 walls. I haven't ran all of the numbers yet but I'm sure I can get the stud walls to work with a minor upgrade as well as the shear walls, roof diaphragm and garage door header. The stemwall foundation and slab have been upgraded by the owner and my experience tells me already that bearing loads won't be a problem either.

Nothing really special going on here other than size which causes me to wonder if at some level I may be overlooking something with respect to a structure of this size. As we begin to scale things up are there other codes or factors that come into play that would not otherwise with a smaller structure. There are no internal walls, just the 4 exterior walls with a 18' wide garage door at one of the gable ends and a 3' man door. From a prescriptive standpoint I know this structure breaks all of the IRC braced wall line rules so the IRC is out of the question on this one.

The reason I have a concern here is based on a conversation I had with an architect on a personal project about 10 years ago. At the time I was involved with my brother in a roofing materials distribution business. Being very young and inexperienced I figured I would design our next warehouse. Ultimately we had to have a architect take it over after my initial attempts. His first comment at my conventially light woof framed structure (100'x60'x20' box) was that it was simply too flimsy at that size and we ended up going with CMU for the 20' high walls.

Also in a recent thread on tall walls I am left wondering if an upgraded wall is necessary on the side walls of this structure what would be easier and more "contractor friendly", 2x6 walls spaced at 12" o/c or 2x8 walls at 16" o/c. I typically don't try and specify over DF No. 2 for studs since I think the expense of No. 1 or SS would be unwarranted, easier to bump up to more studs or deeper studs, at least this is my current thinking which may or may not be correct.

A confused student is a good student.

Nathaniel P. Wilkerson, PE

Today a large garage landed on my desk, conventional light wood frame construction. The only thing that really jumps out at me is the size of this structure. 40'x60' rectangle with 40' trusses on 15' high 2x6 walls. I haven't ran all of the numbers yet but I'm sure I can get the stud walls to work with a minor upgrade as well as the shear walls, roof diaphragm and garage door header. The stemwall foundation and slab have been upgraded by the owner and my experience tells me already that bearing loads won't be a problem either.

Nothing really special going on here other than size which causes me to wonder if at some level I may be overlooking something with respect to a structure of this size. As we begin to scale things up are there other codes or factors that come into play that would not otherwise with a smaller structure. There are no internal walls, just the 4 exterior walls with a 18' wide garage door at one of the gable ends and a 3' man door. From a prescriptive standpoint I know this structure breaks all of the IRC braced wall line rules so the IRC is out of the question on this one.

The reason I have a concern here is based on a conversation I had with an architect on a personal project about 10 years ago. At the time I was involved with my brother in a roofing materials distribution business. Being very young and inexperienced I figured I would design our next warehouse. Ultimately we had to have a architect take it over after my initial attempts. His first comment at my conventially light woof framed structure (100'x60'x20' box) was that it was simply too flimsy at that size and we ended up going with CMU for the 20' high walls.

Also in a recent thread on tall walls I am left wondering if an upgraded wall is necessary on the side walls of this structure what would be easier and more "contractor friendly", 2x6 walls spaced at 12" o/c or 2x8 walls at 16" o/c. I typically don't try and specify over DF No. 2 for studs since I think the expense of No. 1 or SS would be unwarranted, easier to bump up to more studs or deeper studs, at least this is my current thinking which may or may not be correct.

A confused student is a good student.

Nathaniel P. Wilkerson, PE