XR250

Structural

- Jan 30, 2013

- 5,925

This is an 8 ft. span, 3 1/2x9 1/4 beam in the crawlspace of a 2 year old home. It supports 12 ft. trib of floor framing (trussed roof). There are some cracks in the sheetrock near this beam.

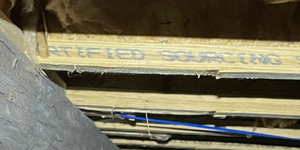

1) What material is this? It looks like crap. It appears to be one 3 1/2" wide ply. Kinda looks like an LVL. Could it be LSL? It has no markings.

2) The beam appears to have slight sagging in each span. I did not have a stringline with me, however.

3) It also appears to be crushed slightly at the edge of each support.

No way this should be sagging at this span with only 12 ft. of mostly floor dead load.

My guess is that it was put up soaking wet which temporarily weakened it and it has shrunk a bit as well.

The owner states the cracks have not worsened in a year.

Thoughts?

1) What material is this? It looks like crap. It appears to be one 3 1/2" wide ply. Kinda looks like an LVL. Could it be LSL? It has no markings.

2) The beam appears to have slight sagging in each span. I did not have a stringline with me, however.

3) It also appears to be crushed slightly at the edge of each support.

No way this should be sagging at this span with only 12 ft. of mostly floor dead load.

My guess is that it was put up soaking wet which temporarily weakened it and it has shrunk a bit as well.

The owner states the cracks have not worsened in a year.

Thoughts?

Last edited: