Anirudh_96

Petroleum

- Apr 7, 2025

- 8

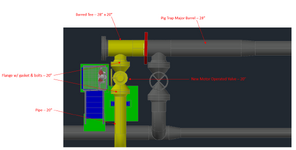

Hello, I'm designing a pipeline connecting to a 28" pig trap via a 28" x 20" Reducing tee via a Weldneck Flange and a spool of 20" pipe. Pressure class of the piping is 600#. We've received a Piping Material Specification from our client that specifies the materials as :

Pipe - API 5L Gr. X65 PSL2, SMYS - 65000 psi

Flange - ASTM A105N (600#, WNRF) , SMYS - 36000 psi

Tee - ASTM A860 Gr. WPHY, SMYS - 65000 psi

Thickness of all three items is 1/2".

I'm still fairly new to materials but I'm concerned if these materials can be used together given the large difference in yield strength. I'd also like to know if there are any concerns on welding as well.

Thanks in advance!

Pipe - API 5L Gr. X65 PSL2, SMYS - 65000 psi

Flange - ASTM A105N (600#, WNRF) , SMYS - 36000 psi

Tee - ASTM A860 Gr. WPHY, SMYS - 65000 psi

Thickness of all three items is 1/2".

I'm still fairly new to materials but I'm concerned if these materials can be used together given the large difference in yield strength. I'd also like to know if there are any concerns on welding as well.

Thanks in advance!

![[ponder] [ponder] [ponder]](/data/assets/smilies/ponder.gif)