medeek

Structural

- Mar 16, 2013

- 1,104

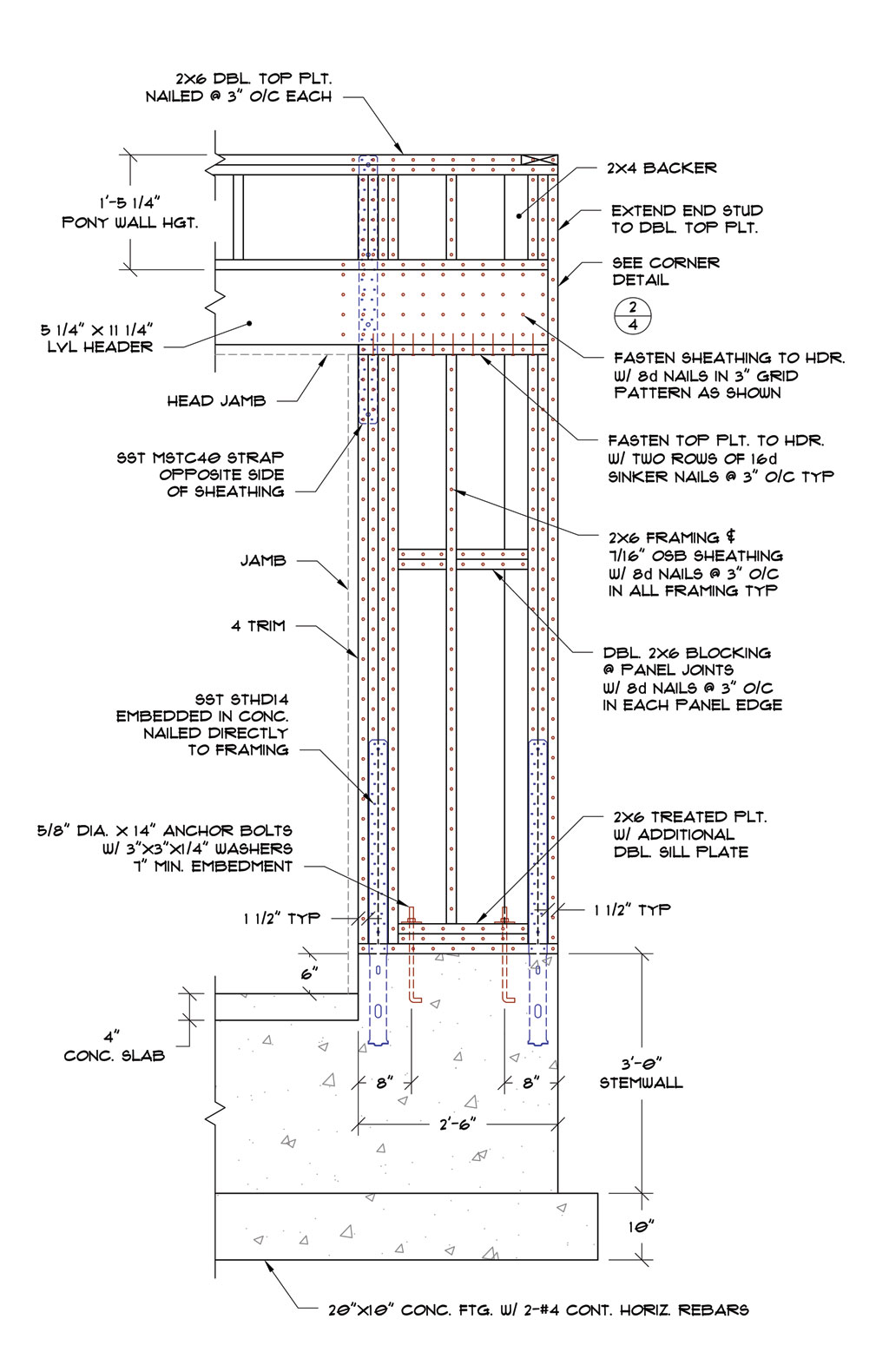

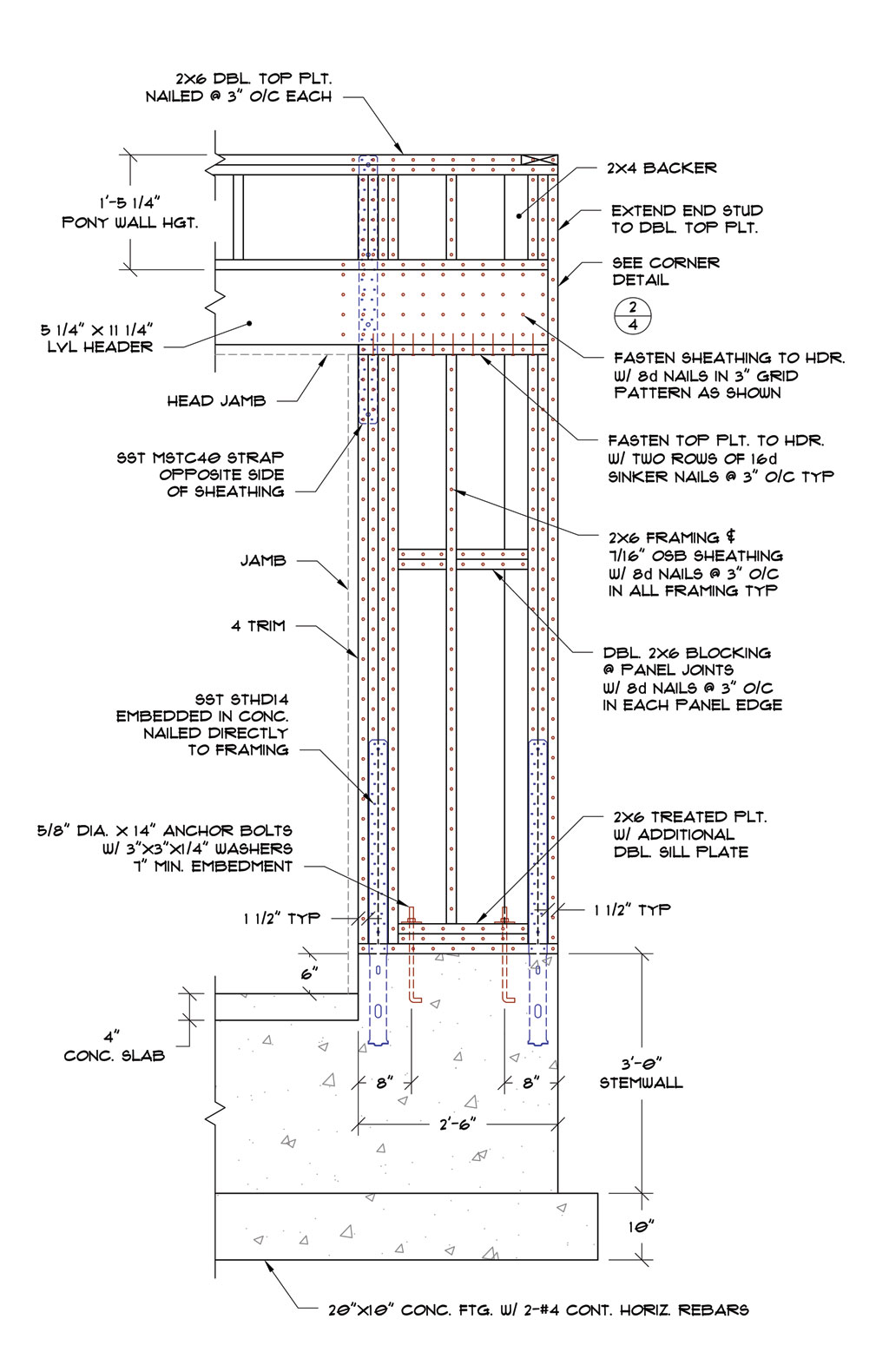

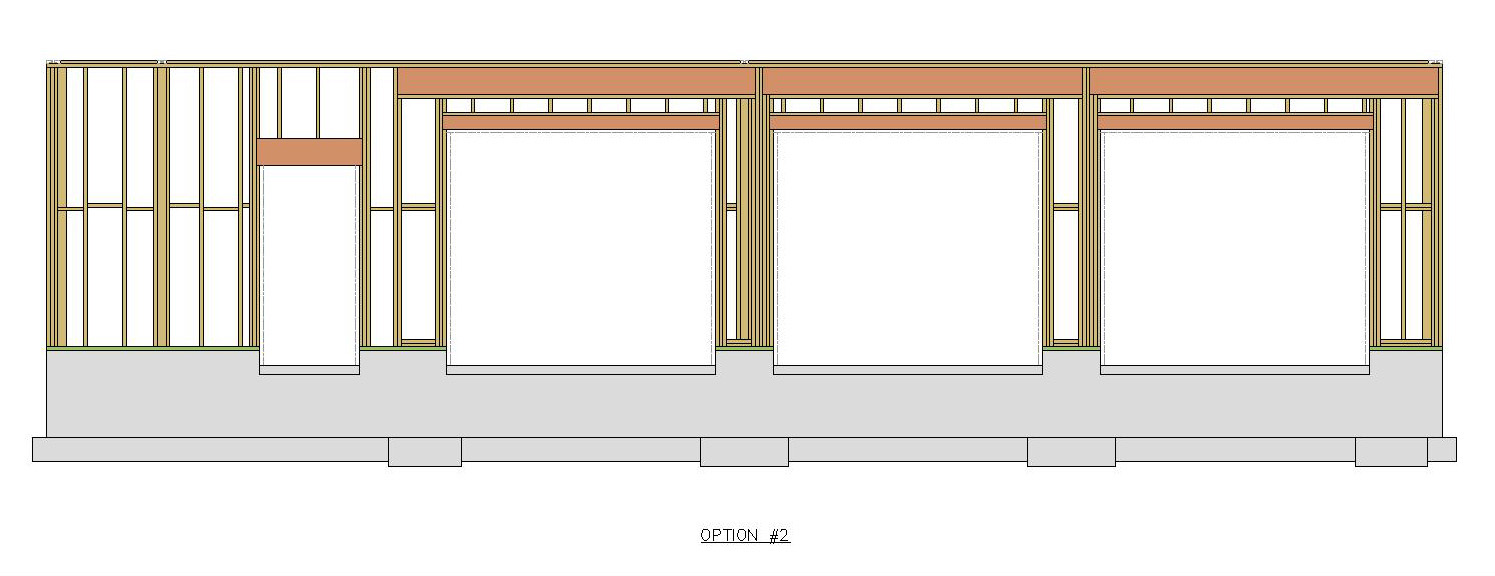

Due to the overwhelmingly positive feedback I received on my questions about the foundation/driveway question I thought I might post up one other item that has been bugging me for a while. I drew up this portal frame detail to show the nailing pattern per code so that a person with little or no construction experience could properly nail off the OSB so that it is structurally sound. However, with all those nails the whole thing looks like swiss cheese to me. Any ideas on the "correct" nailing pattern. I am trying to comply with the IRC 2012 nailing requirements for this type of portal frame.