PFBlowerinstall

Industrial

- Mar 12, 2022

- 7

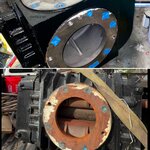

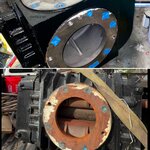

I have a question regarding PD blower. Maybe someone can advise. I have a roots PD blower (616 dvj) I purchased new. The unit sat for a good year or so - covered with a tarp and now im needing to clean it up (Without taking it apart) any experience with this process. quickest methods that won’t harm the lobes