Hi,

First post...

I'm an electrical engineer that tinkers with mechanics as a hobby. I'm adding CNC capability to my 10x22 lathe.

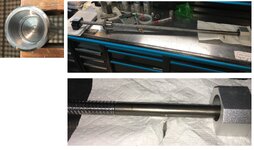

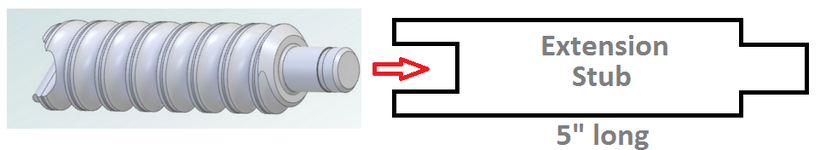

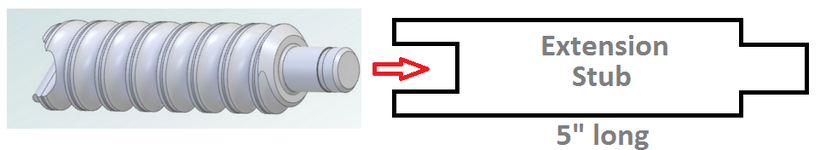

I have a ballscrew for the Z axis. It's long enough to allow full carriage travel, however if I could extend the not threaded floating end by 5" it would make mounting the floating end much easier. The captive end is mounted in a bearing block with a lock-nut that prevents movement along the length of the ballscrew. So the floating end just floats.

The shaft size at the floating end (reduced diameter stub) is 15mm in diameter to match the bearing in the floating end bearing block.

Plan is to make a 5" stub starting with a 20mm steel round I happen to have on hand and boring a 15mm hole (interference fit) to mate with the 15mm stub on the end of the ballscrew, and then machine the other end of the round to 15mm to match the bearing in the bearing block.

Plan is to put the ballscrew in the freezer, and the new 5" stub in the oven and then quickly tap the two together to hopefully lock the new stub to the end of the ballscrew.

Question #1 how much under size should that 15mm hole be to; be tight enough to lock the new stub to the ballscrew but not be so tight that the frozen ballscrew and heated stub won't go together with a few taps of a brass hammer?

Question # 2 in a perfect world the new stub will be perfectly aligned with the ballscrew, but this is not a perfect world so I'm thinking I should probably machine the 15mm end of the new stub after it's mated to the ballscrew even though it would be easier to do it before hand. Thoughts?

First post...

I'm an electrical engineer that tinkers with mechanics as a hobby. I'm adding CNC capability to my 10x22 lathe.

I have a ballscrew for the Z axis. It's long enough to allow full carriage travel, however if I could extend the not threaded floating end by 5" it would make mounting the floating end much easier. The captive end is mounted in a bearing block with a lock-nut that prevents movement along the length of the ballscrew. So the floating end just floats.

The shaft size at the floating end (reduced diameter stub) is 15mm in diameter to match the bearing in the floating end bearing block.

Plan is to make a 5" stub starting with a 20mm steel round I happen to have on hand and boring a 15mm hole (interference fit) to mate with the 15mm stub on the end of the ballscrew, and then machine the other end of the round to 15mm to match the bearing in the bearing block.

Plan is to put the ballscrew in the freezer, and the new 5" stub in the oven and then quickly tap the two together to hopefully lock the new stub to the end of the ballscrew.

Question #1 how much under size should that 15mm hole be to; be tight enough to lock the new stub to the ballscrew but not be so tight that the frozen ballscrew and heated stub won't go together with a few taps of a brass hammer?

Question # 2 in a perfect world the new stub will be perfectly aligned with the ballscrew, but this is not a perfect world so I'm thinking I should probably machine the 15mm end of the new stub after it's mated to the ballscrew even though it would be easier to do it before hand. Thoughts?

Last edited: