Morning all,

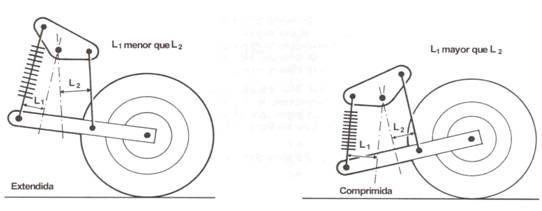

referring to magazine Race car Engineering V9n1 Jan/Feb 1999 page 76 would anyone care to make comment or does anyone know if this layout has gone anywere, I cannot see any advantages and I do not understand the statement "fully floating spring damper unit". I was approached recently about this concept and recall reading it albeit 15 years ago, have reread but it still does not make sense to me apart from the fact that I would not like to do the "calcs" to determine the value of the

'spring/resistance" to bending, don,t know what to call it! Comments etc greatly appreciated.

Golfpin

referring to magazine Race car Engineering V9n1 Jan/Feb 1999 page 76 would anyone care to make comment or does anyone know if this layout has gone anywere, I cannot see any advantages and I do not understand the statement "fully floating spring damper unit". I was approached recently about this concept and recall reading it albeit 15 years ago, have reread but it still does not make sense to me apart from the fact that I would not like to do the "calcs" to determine the value of the

'spring/resistance" to bending, don,t know what to call it! Comments etc greatly appreciated.

Golfpin