resilientsoma

Mechanical

- Jul 11, 2012

- 34

Hello all,

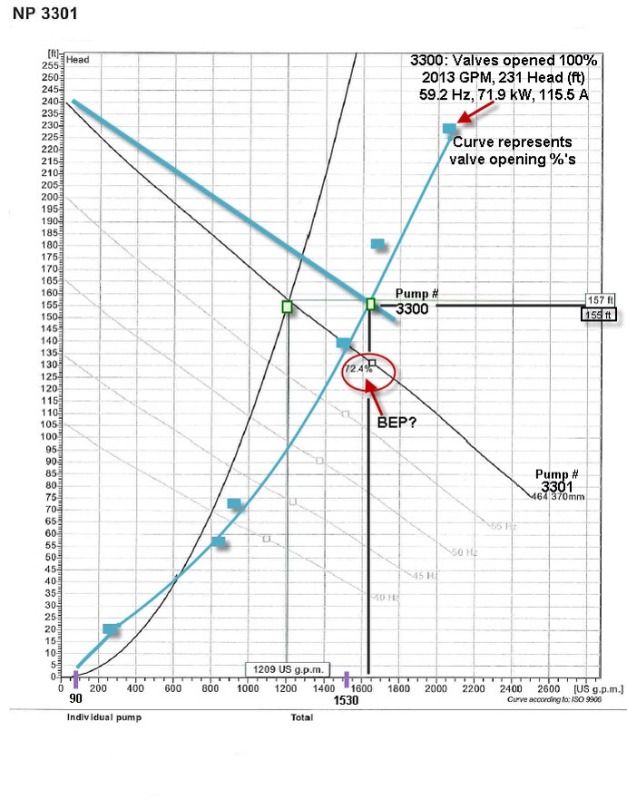

When looking at a pump curve, how do you determine if it's safe to run at a certain GPM without causing harm to the pump internals (seals, bearings, impeller).

For example, FLYGT 3300.181 : CLICK FOR SPECS

If I ran my system at 90 GPM, would this be okay and why (please feed me some basics)? If not, what can be the damage? Anything to recommend or change in the system besides picking a new pump?

Your help is greatly appreciated. I'm a new engineer; hopefully I'll be able to help someone later on!!!

When looking at a pump curve, how do you determine if it's safe to run at a certain GPM without causing harm to the pump internals (seals, bearings, impeller).

For example, FLYGT 3300.181 : CLICK FOR SPECS

If I ran my system at 90 GPM, would this be okay and why (please feed me some basics)? If not, what can be the damage? Anything to recommend or change in the system besides picking a new pump?

Your help is greatly appreciated. I'm a new engineer; hopefully I'll be able to help someone later on!!!