resilientsoma

Mechanical

Hello All,

I'm new, but have been browsing your forums for quite some time. Please point me in the correct direction with my current problem:

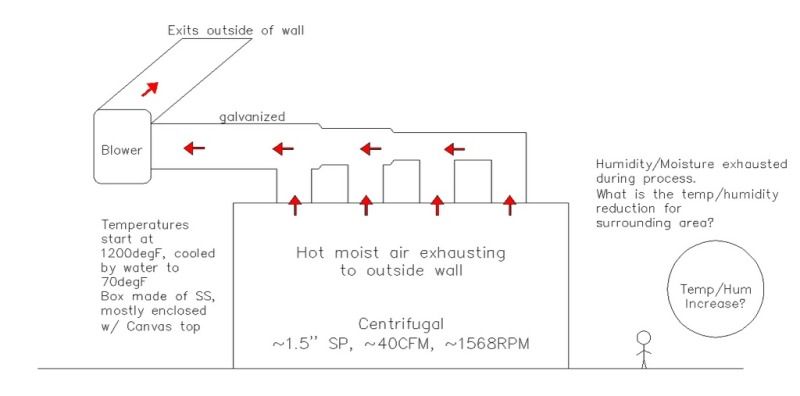

In my plant we use a water-cooling system which generates a lot of heat. I have proposed to use a centrifugal blower to pull this moisture/humidity out of this area which is mostly enclosed. Before hand, it was making the surrounding areas very hot and humid. Making the area more enclosed and having a blower pulling out the moisture/humidity, is there a calculation to use to determine the reduction in temperature and humidity?

The information I have is temperature for the enclosed area (water cooling system), temperature/RH/dewpoint of surrounding areas, CFM and SP of blower.

Basically trying to figure out if there is a reduction calculation or only assume ambient effects being enclosed. The enclosed area is a stainless steel housing with a canvas roof.

I'm sorry for not being more specific, your help is greatly appreciated. Thank you!

I'm new, but have been browsing your forums for quite some time. Please point me in the correct direction with my current problem:

In my plant we use a water-cooling system which generates a lot of heat. I have proposed to use a centrifugal blower to pull this moisture/humidity out of this area which is mostly enclosed. Before hand, it was making the surrounding areas very hot and humid. Making the area more enclosed and having a blower pulling out the moisture/humidity, is there a calculation to use to determine the reduction in temperature and humidity?

The information I have is temperature for the enclosed area (water cooling system), temperature/RH/dewpoint of surrounding areas, CFM and SP of blower.

Basically trying to figure out if there is a reduction calculation or only assume ambient effects being enclosed. The enclosed area is a stainless steel housing with a canvas roof.

I'm sorry for not being more specific, your help is greatly appreciated. Thank you!