Nejim

Electrical

- Nov 6, 2014

- 2

Hello All

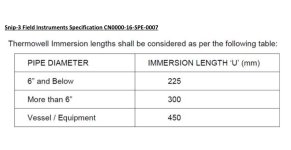

Q1: For installing thermowell on a 2”pipe, is it advisable to increase pipe size to 6” and then reduce the pipe back to 2inch?

Q2: Is there a limit defined for Nozzle standout(shielded length) for vessels?Is it abnormal to have Nozzle length of 1800mm?

Q1: For installing thermowell on a 2”pipe, is it advisable to increase pipe size to 6” and then reduce the pipe back to 2inch?

Q2: Is there a limit defined for Nozzle standout(shielded length) for vessels?Is it abnormal to have Nozzle length of 1800mm?