dgengineering

Structural

Hi everyone,

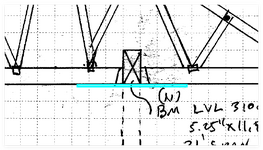

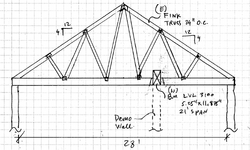

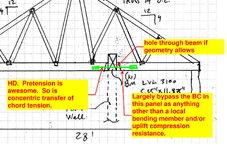

I have a remodeling project and it's under construction now. The builders cut the existing truss bottom chord to place a 21' span beam where the wall used to be. The inspector wants approval for this.

The beam was designed for ceiling loads since the architectural plans didn't show trusses. How do I determine if the truss cut will add more load to the beam or not. Also, how much load should I use to check the beam strength again. See my sketch

Thanks

I have a remodeling project and it's under construction now. The builders cut the existing truss bottom chord to place a 21' span beam where the wall used to be. The inspector wants approval for this.

The beam was designed for ceiling loads since the architectural plans didn't show trusses. How do I determine if the truss cut will add more load to the beam or not. Also, how much load should I use to check the beam strength again. See my sketch

Thanks