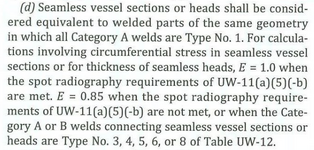

Hello, Very new to pressure vessel design. Our AI has asked for UG-34 calculations on a manway blind. based on its type the UG-34 calculations button that usually is available is not for this opening. I have tried to just read the book and do the calculations by hand but I don't understand which equation to use. I figure it matches sketches j & k the best but the equation for them refers to a welded joint and this cover is bolted on. am I supposed to use the weld where the manway meets the head? can someone talk me through this. Compress photo below.