I'm having an issue understanding the answers to the following questions. They're from a practice exam for the GD&T senior certification.

1) A tolerance of position or orientation is totally dependent on the size of unrelated actual minimum material envelope of the considered feature when the tolerance is

a) basic, b) zero at lmc, c) next to the size dimension, d) zero at mmc

2) A tolerance of position or orientation is totally dependent on the size of unrelated actual mating envelope of the considered feature when the tolerance is

a) basic, b) zero at lmc, c) next to the size dimension, d) zero at mmc.

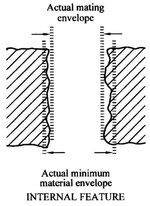

The part that is confusing me is the use of minimum material envelope and mating envelope. I may not have a good understanding of their definition and how they apply to zero at mmc/lmc cases.

Thanks,

Dan

1) A tolerance of position or orientation is totally dependent on the size of unrelated actual minimum material envelope of the considered feature when the tolerance is

a) basic, b) zero at lmc, c) next to the size dimension, d) zero at mmc

2) A tolerance of position or orientation is totally dependent on the size of unrelated actual mating envelope of the considered feature when the tolerance is

a) basic, b) zero at lmc, c) next to the size dimension, d) zero at mmc.

The part that is confusing me is the use of minimum material envelope and mating envelope. I may not have a good understanding of their definition and how they apply to zero at mmc/lmc cases.

Thanks,

Dan