sendithard

Industrial

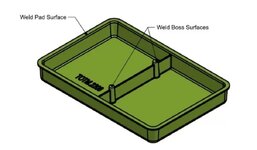

We just onboarded a new customer. All their prints have unequally disposed surface profiles. And their CAD models are all made at MMC condition. That causes some issues with surface hits on the CMM with tight tolerances. So I'm in the middle of altering their models to what we make the parts at. We are dealing with some goofy .05/.025mm profiles on position and profile, which is basically beyond the capability in my opinion of our CMM. I'm trying to get a Gage RR done at the moment on these ridiculous internal callouts,. Uncertainty is at a minimum of 2 tenths or 5 microns.

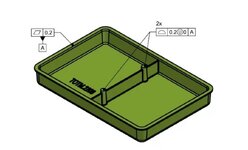

GDT is for communication. Can someone explain to me why you would ever desire to basic a print at the MMC with one sided tolerance? What is wrong with the basic at what the part should be made at and a bi-lateral tolerance zone?

The customer just provided a print at Profile .025 U 0 and the tolerance zone is dashes in the direction the part can grow which is opposite the callout. They don't understand the callout nor do our engineers. Run an external profile of .025 U 0 by two random engineers and then run an internal profile of .025 U 0 by them later in the day and see if you get the right answers. No chance. I cannot stand unilateral tolerances, and would enjoy hearing why anyone would use them?

Thanks.

GDT is for communication. Can someone explain to me why you would ever desire to basic a print at the MMC with one sided tolerance? What is wrong with the basic at what the part should be made at and a bi-lateral tolerance zone?

The customer just provided a print at Profile .025 U 0 and the tolerance zone is dashes in the direction the part can grow which is opposite the callout. They don't understand the callout nor do our engineers. Run an external profile of .025 U 0 by two random engineers and then run an internal profile of .025 U 0 by them later in the day and see if you get the right answers. No chance. I cannot stand unilateral tolerances, and would enjoy hearing why anyone would use them?

Thanks.

Last edited: