SALTRAM4567777

Structural

- Aug 11, 2020

- 90

"Hello everyone,

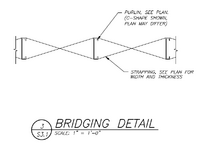

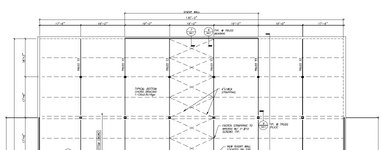

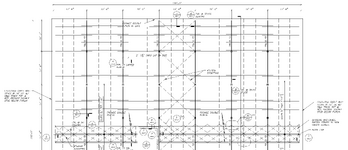

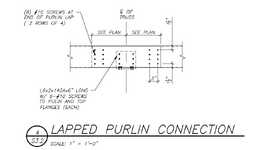

I'm reviewing a design featuring purlins supporting a standing seam roof. Since the purlins are unrestrained the top as well as bottom flange, I need to design for both gravity and wind uplift loads. To prevent lateral-torsional buckling (LTB), I want to implement a bridging system to restrain both the top and bottom flanges.

The roof has a monoslope configuration with a slope of 5 degrees.

Would a rigid fixed strut system with diagonals at the ends be an effective solution?

What about Sag rods top to purlin bottom with diagnols at end on ridge.

I'm reviewing a design featuring purlins supporting a standing seam roof. Since the purlins are unrestrained the top as well as bottom flange, I need to design for both gravity and wind uplift loads. To prevent lateral-torsional buckling (LTB), I want to implement a bridging system to restrain both the top and bottom flanges.

The roof has a monoslope configuration with a slope of 5 degrees.

Would a rigid fixed strut system with diagonals at the ends be an effective solution?

What about Sag rods top to purlin bottom with diagnols at end on ridge.