mikevaughn

Mechanical

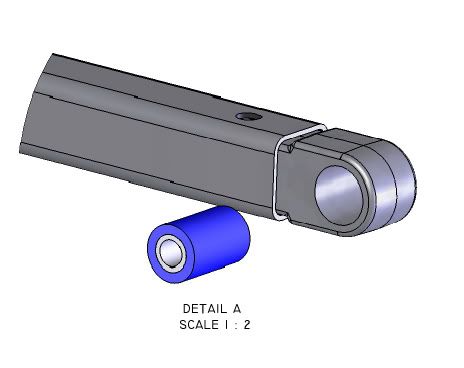

I currenly design a lot of weldments using square tubing and fabricated brackets. I would like to create some molded shapes to simplify the fabrication process. I know that welding cast iron is not feasable, but can you weld cast steel easily??

I am thinking of a similar material situation that you would have when making a drive shaft assembly. A tube welded to a structural shape (yoke). My question is "what is the material and manufacturing process used to make that structural shape"? Is is cast, or is it forged... or something else? Please help.

I am thinking of a similar material situation that you would have when making a drive shaft assembly. A tube welded to a structural shape (yoke). My question is "what is the material and manufacturing process used to make that structural shape"? Is is cast, or is it forged... or something else? Please help.