Hello everyone. Why are intermittent groove/butt welds prohibited, with either full or partial penetration? This is specified in the European design code (Eurocode 3). I am not familiar with other standards, but I see this is also specified in AWS D1.1 (4.8.2). Please correct me if I misunderstand. I'm not looking at a particular connection (example), just the reasoning behind it (in principle). Does is have anything to do with the type of loads applied (static or dynamic), fatigue etc. Thank you in advance.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations MintJulep on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why are intermittent groove/butt welds prohibited? 3

- Thread starter SSM_27

- Start date

- Status

- Not open for further replies.

Butt welds are not meant to be calculated (see EC3), because a butt weld should develop the same strength as the base material(s).

This principle does not work anymore if you're going to introduce intermittent Butt welds.

Also, for most applications, they're not the greatest ideas (but that's up to your interpretation).

ANother reason is for corrosion protection coatings. Grooves will rust from inside out, even when hot dip galvanised or powder coated.

This principle does not work anymore if you're going to introduce intermittent Butt welds.

Also, for most applications, they're not the greatest ideas (but that's up to your interpretation).

ANother reason is for corrosion protection coatings. Grooves will rust from inside out, even when hot dip galvanised or powder coated.

- Thread starter

- #4

Thank you both for your answers.

@kingnero

I am aware full penetration welds are not calculated. Are you saying the same principle that applies to intermittent fillet welds cannot be applied to intermittent butt welds (in terms of how they are designed)? Take for example a build up I section beam, simply supported, uniform distributed load, the simplest situation (static load). So ignoring corrosion protection.

Yes, intermittent welds of any kind are forbidden in corrosive conditions. That I can understand why.

A more concrete example: a colleague asked for my opinion on the welds for a build up cross section from one of his projects (see attachment). This was proposed by the manufacturer. The architect requested that the welds (marked as butt welds) should not be visible (flush finish). Any opinion is appreciated.

@kingnero

I am aware full penetration welds are not calculated. Are you saying the same principle that applies to intermittent fillet welds cannot be applied to intermittent butt welds (in terms of how they are designed)? Take for example a build up I section beam, simply supported, uniform distributed load, the simplest situation (static load). So ignoring corrosion protection.

Yes, intermittent welds of any kind are forbidden in corrosive conditions. That I can understand why.

A more concrete example: a colleague asked for my opinion on the welds for a build up cross section from one of his projects (see attachment). This was proposed by the manufacturer. The architect requested that the welds (marked as butt welds) should not be visible (flush finish). Any opinion is appreciated.

TugboatEng

Marine/Ocean

To come at this from another angle, if you have a member has so much excess strength that it does not require full welding, perhaps you should consider reducing the size of the member.

SSM 27 said:Are you saying the same principle that applies to intermittent fillet welds cannot be applied to intermittent butt welds (in terms of how they are designed)? Take for example a build up I section beam, simply supported, uniform distributed load, the simplest situation (static load).

No, I'm saying that it is consistent in the eurocodes that butt welds don't have to be calculated and that intermittent butt welds cannot be used.

These two statements are to be read together.

No problem to deviate from this. It is done all the time. Just make sure you can back up your decision.

SSM_27 said:Why are intermittent groove/butt welds prohibited, with either full or partial penetration? This is specified in the European design code (Eurocode 3). I am not familiar with other standards, but I see this is also specified in AWS D1.1 (4.8.2). Please correct me if I misunderstand.

I can't speak to Eurocode, however AWS D1.1 does allow for intermittent PJP groove welds. The clause you sited above (4.8.2) is specifically for CJP groove welds. The following clause (4.8.3) states: "Intermittent PJP groove welds, flare bevel, and flare-groove welds may be used to transfer shear stress between connected parts."

-

1

- #13

- Thread starter

- #16

@kingnero

Yes, I understand what you are saying, those 2 (butt welds are not calculated and intermittent butt welds are forbidden) are used in conjunction.

In my example (the build up I beam): if intermittent fillet welds are ok to transfer sheer stress between flanges and web (for a particular loading situation and layout of the welds), can't those be replaced with full or partial penetration welds? Even if they are designed and the resistance (for full penetration I mean) is not considered as the design resistance of the parts connected.

I know people deviate from this. Without knowing why they are prohibited in the first place, how can I justify my decision?

@dauwerda

Indeed clause 4.8.3 specifies what you said. Thanks for pointing that out, don't know how I missed it.

Going back to my original question, do you know the reason behind these conditions? Why one is prohibited and the other not?

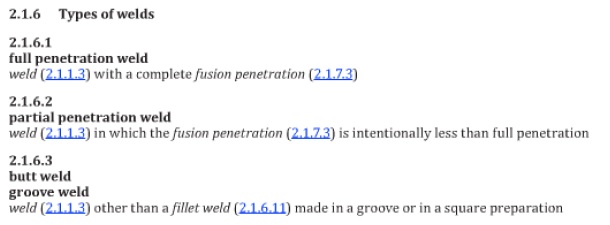

about butt welds definition

Yes, the welds in the sketch I attached are not by definition butt welds (in my native language they are called "head to head welds", ad litteram). I suppose they can be considered as T-butt joints. In my experience, people (English natives) refer to all welds that require prepped edges as butt welds. In my native language all welds that require prepped edges are called "depth welds" (ad litteram) and butt welds ("head to head") fall in this category.

Eurocode references (EN 1993-1-8):

[ul]

[li]T-butt joints - 4.7.3[/li]

[li]Intermittent butt welds - 4.3.4[/li]

[/ul]

Yes, I understand what you are saying, those 2 (butt welds are not calculated and intermittent butt welds are forbidden) are used in conjunction.

In my example (the build up I beam): if intermittent fillet welds are ok to transfer sheer stress between flanges and web (for a particular loading situation and layout of the welds), can't those be replaced with full or partial penetration welds? Even if they are designed and the resistance (for full penetration I mean) is not considered as the design resistance of the parts connected.

I know people deviate from this. Without knowing why they are prohibited in the first place, how can I justify my decision?

@dauwerda

Indeed clause 4.8.3 specifies what you said. Thanks for pointing that out, don't know how I missed it.

Going back to my original question, do you know the reason behind these conditions? Why one is prohibited and the other not?

about butt welds definition

Yes, the welds in the sketch I attached are not by definition butt welds (in my native language they are called "head to head welds", ad litteram). I suppose they can be considered as T-butt joints. In my experience, people (English natives) refer to all welds that require prepped edges as butt welds. In my native language all welds that require prepped edges are called "depth welds" (ad litteram) and butt welds ("head to head") fall in this category.

Eurocode references (EN 1993-1-8):

[ul]

[li]T-butt joints - 4.7.3[/li]

[li]Intermittent butt welds - 4.3.4[/li]

[/ul]

r6155,

My apologies - you are correct when referencing AWS D1.1.

Obviously depends on which part of the world you are from - Eurocode above as example.

Another example - Australian standard AS/NZS 1554.1 - " The size of a complete penetration T-joint or corner joint butt weld shall be the thickness of the

part that butts against the face of the other part.

" Butt-welded T-joints may have a small fillet weld superimposed on each welded face............"

Then we have the differences in various codes / standards regarding butt joints and butt welds (the OP referenced butt welds).

Cheers,

Shane

My apologies - you are correct when referencing AWS D1.1.

Obviously depends on which part of the world you are from - Eurocode above as example.

Another example - Australian standard AS/NZS 1554.1 - " The size of a complete penetration T-joint or corner joint butt weld shall be the thickness of the

part that butts against the face of the other part.

" Butt-welded T-joints may have a small fillet weld superimposed on each welded face............"

Then we have the differences in various codes / standards regarding butt joints and butt welds (the OP referenced butt welds).

Cheers,

Shane

I think what’s important here, rather than arguing semantics of butt weld vs corner joint vs whatever, is that the OP has also referred to them as groove welds. And that’s all that really matters.

The devil is in the details; she also wears prada.

The devil is in the details; she also wears prada.

-

1

- #19

dik said:Even with prepared edges? ponder

r6155 said:kingnero

Can you tell us the exact reference?

By definition (ISO/TR 25901-1), a butt weld is:

Fillet welds never have any preparation like bevels under ISO.

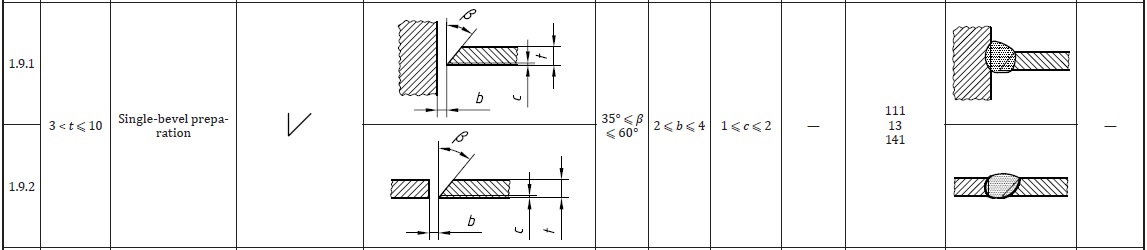

Under ISO 9692-1, this preparation falls under butt welds:

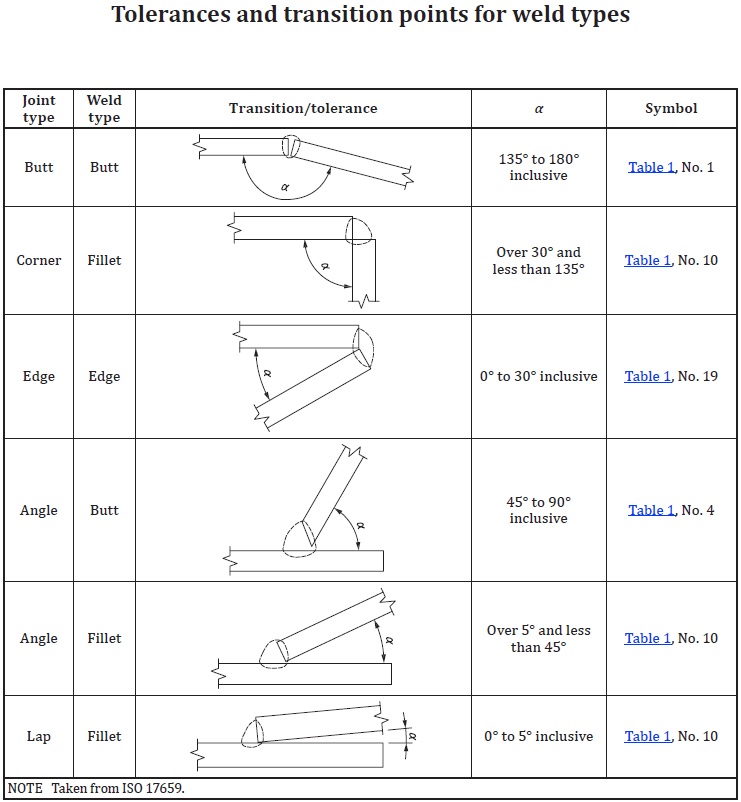

You'll see, 45° to 90° angles with bevels are classified as butt welds also under ISO 2553:

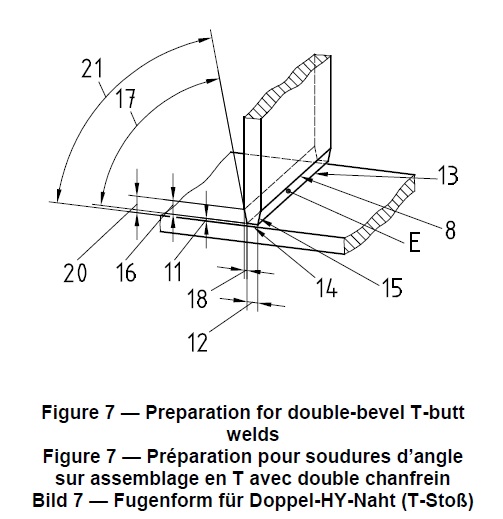

I couldn't find an example of a single sided similar weld (and there are almost no examples of incomplete penetration butt welds in these standards), but I hope this gives another example that strengthens the point I'm trying to make:

-

1

- #20

- Status

- Not open for further replies.

Similar threads

- Question

- Replies

- 13

- Views

- 10K

- Question

- Replies

- 4

- Views

- 720

- Locked

- Question

- Replies

- 3

- Views

- 1K

- Locked

- Replies

- 5

- Views

- 5K

- Locked

- Question

- Replies

- 3

- Views

- 814

![[ponder] [ponder] [ponder]](/data/assets/smilies/ponder.gif)