_Conky

Structural

- Mar 12, 2024

- 8

Hey all, just looking for ideas or suggestions on detailing this issue. Doing 1.5 storey addition all wood framed on top of an existing bungalow, working for an architect who is handling all of the non-structural.

During permit process the City decided they wanted non-combustible walls, so walls changed to LGS studs....a previously used detail was submitted with the wood floor & rim joists sandwiched between upper and lower steel stud walls, with exterior steel cover plate and firestop to protect the wood. Now they have decided they don't like that anymore and the wood floor can't penetrate into the lgs stud wall at all.

Owner/architect wants to keep all wood framing where possible so looking to connect the wood floor to the lgs studs. So far I can think of two options:

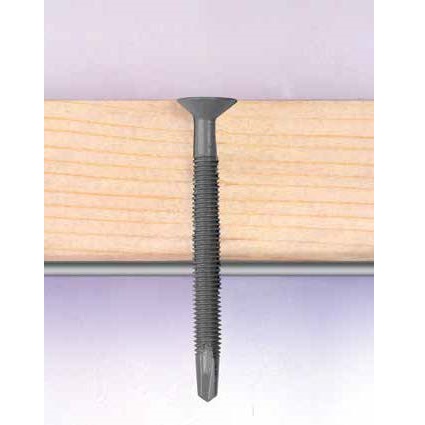

1. Fasten a 2x12 or LSL ledger to the face of the lgs studs with SDS screws, but finding the correct screw is a bit tricky. Lots of options for wood to steel found but most are meant for plywood to LGS, or meant for 2x wood to hot rolled steel. Anyone know a suitable product for 2x wood to lgs, that has published load ratings?

2. Hang the joists directly on the lower LGS stud wall top track with top flange mount joist hangers, then stack upper wall on that. Seems simple enough but need a hanger that is approved for top flange mount to LGS...hangers so far I've found say for bearing on 1/4 to 1/2 steel. Also I would think there would be a gap between the top track of the low wall and bottom track of the upper wall, a gap the thickness of the hanger flange plus fastener heads. So some sort of 1/8-1/4" filler plate would be needed to fill that gap for even bearing of the wall above.

3. Any other suggestions??

Thanks.

During permit process the City decided they wanted non-combustible walls, so walls changed to LGS studs....a previously used detail was submitted with the wood floor & rim joists sandwiched between upper and lower steel stud walls, with exterior steel cover plate and firestop to protect the wood. Now they have decided they don't like that anymore and the wood floor can't penetrate into the lgs stud wall at all.

Owner/architect wants to keep all wood framing where possible so looking to connect the wood floor to the lgs studs. So far I can think of two options:

1. Fasten a 2x12 or LSL ledger to the face of the lgs studs with SDS screws, but finding the correct screw is a bit tricky. Lots of options for wood to steel found but most are meant for plywood to LGS, or meant for 2x wood to hot rolled steel. Anyone know a suitable product for 2x wood to lgs, that has published load ratings?

2. Hang the joists directly on the lower LGS stud wall top track with top flange mount joist hangers, then stack upper wall on that. Seems simple enough but need a hanger that is approved for top flange mount to LGS...hangers so far I've found say for bearing on 1/4 to 1/2 steel. Also I would think there would be a gap between the top track of the low wall and bottom track of the upper wall, a gap the thickness of the hanger flange plus fastener heads. So some sort of 1/8-1/4" filler plate would be needed to fill that gap for even bearing of the wall above.

3. Any other suggestions??

Thanks.