I've done some work analyzing and programming a truss calculator for MPC wood trusses however I've put that project on hold and I'm not looking at trusses made with plywood gussets. I'm not finding a significant amount of information online regarding these types of trusses. Does anyone have any links or even books they could recommend. I would like to create a truss calculator for this type of truss that is similar to the previous calculator I started working on, however this time I will incorporate the wind and snow load cases as well as engineer the gusset plates (ring shank nails and glue).

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations cowski on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wood Gusset Connected Trusses

- Thread starter medeek

- Start date

- Status

- Not open for further replies.

I don't know of any books on the subject offhand. I designed a garage roof using wood gusseted trusses several years ago. I specified nails and glue, but did not rely on the glue to transfer any load.

The amount of labor required to assemble the trusses tended to make the system uneconomical compared to trusses fabricated with light gauge steel truss plates, but the client wanted to do the work himself and was prepared to invest sufficient labor of his own to complete the project. Lots of nails on that job.

BA

The amount of labor required to assemble the trusses tended to make the system uneconomical compared to trusses fabricated with light gauge steel truss plates, but the client wanted to do the work himself and was prepared to invest sufficient labor of his own to complete the project. Lots of nails on that job.

BA

- Thread starter

- #3

Can you tell me anything about the nails you used and any calculations you used to specify the nails and nailing patterns?

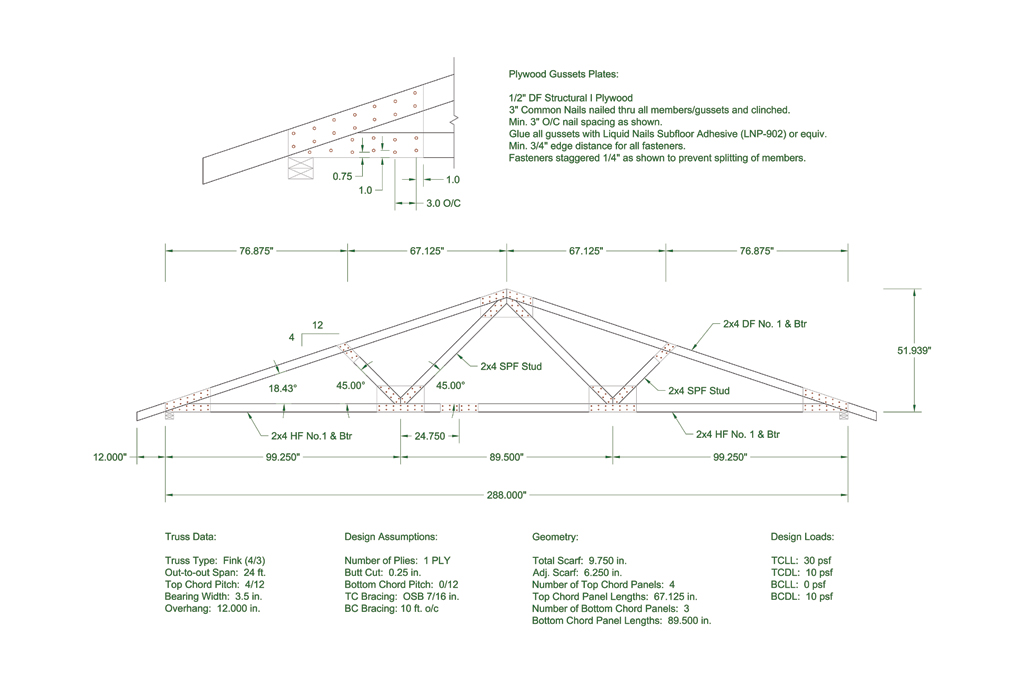

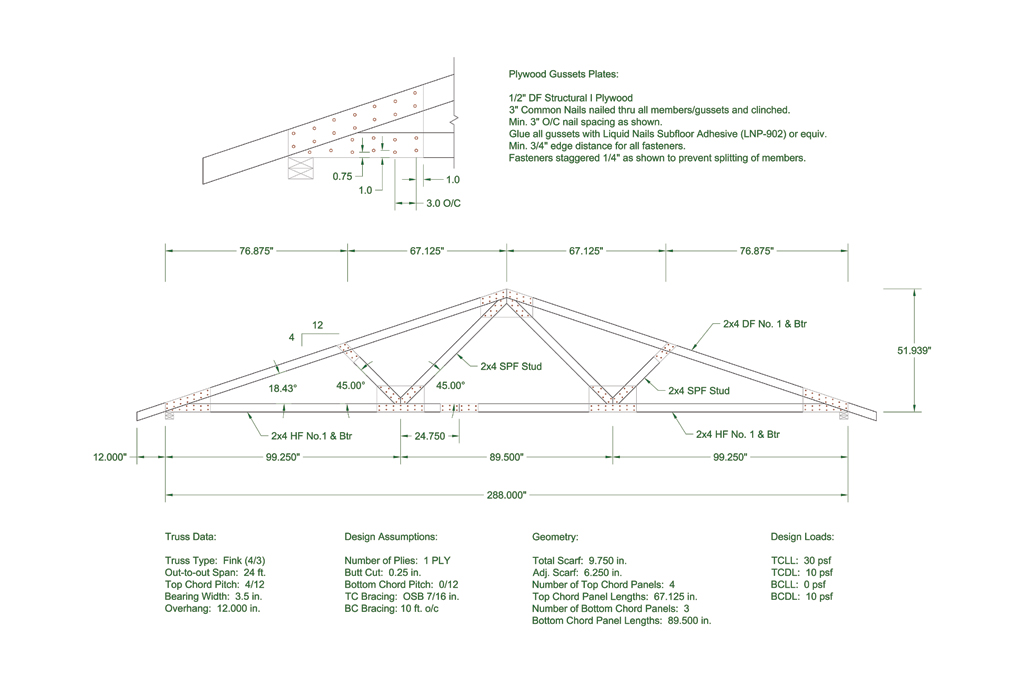

I'm researching methods used in fabricating with plywood gussets. I'm also of the same thinking with the glue, use it, but do not rely upon it in the engineering calculations, it just adds an additional factor of safety. As far as glue is concerned I'm currently looking at Liquid Nails (LNP-902) Subfloor Adhesive and Loctite PL Premium Fast Grab Construction Adhesive, both glues seem to have the right characteristics for this application.

I'm also trying to determine if using 3" nails clinched on the backside is superior to using smaller 6d or 8d ringshank nails (more fasteners). My thinking is that larger nails would be less in number but they may tend to split the members more than a smaller nail would. The downside of the smaller nail of course is more nails to have to nail to get the required strength, so more labor.

For the gussets themselves I've been reading a lot of interesting information on the Plywood vs. OSB. The one thing that makes me lean more toward plywood is that it doesn't swell when it gets wet which could be a problem for OSB before the roof sheathing is applied. I'm thinking 1/2 DF Structural I plywood.

I'm researching methods used in fabricating with plywood gussets. I'm also of the same thinking with the glue, use it, but do not rely upon it in the engineering calculations, it just adds an additional factor of safety. As far as glue is concerned I'm currently looking at Liquid Nails (LNP-902) Subfloor Adhesive and Loctite PL Premium Fast Grab Construction Adhesive, both glues seem to have the right characteristics for this application.

I'm also trying to determine if using 3" nails clinched on the backside is superior to using smaller 6d or 8d ringshank nails (more fasteners). My thinking is that larger nails would be less in number but they may tend to split the members more than a smaller nail would. The downside of the smaller nail of course is more nails to have to nail to get the required strength, so more labor.

For the gussets themselves I've been reading a lot of interesting information on the Plywood vs. OSB. The one thing that makes me lean more toward plywood is that it doesn't swell when it gets wet which could be a problem for OSB before the roof sheathing is applied. I'm thinking 1/2 DF Structural I plywood.

The truss members were 2x4. The gussets were 1/2" Fir Ply. The nails were 2.5" common wire nails driven alternately from both sides, a code requirement when nails are not clinched. Spacing and allowable load per nail was in accordance with the code of the day, which I believe was CSA086-1980.

You should get a copy of the latest version of CSA086 or other timber code applicable to your area. The latest I have is CSA086-2001 but I am pretty sure there are more recent codes available today.

BA

You should get a copy of the latest version of CSA086 or other timber code applicable to your area. The latest I have is CSA086-2001 but I am pretty sure there are more recent codes available today.

BA

EngineeringEric

Structural

You have to clinch the nails if you want to utilize each nail as a double shear connection. There have been technical reports on your question. typically for repairing broken trusses in the field. 1/2+1.5"+1/2"=2.5" => use 3" nails, cinched in double shear, both sides, spaced a 2-3" o.c. to reduce splitting of the 2x member.

I second BA, use glue but do not transfer any load to the glue.

I second BA, use glue but do not transfer any load to the glue.

The most current CSA O86 is 2009 for those that care. If you are buying it packaged inside the wood design manual (which I highly suggest) the most current edition of that book is 2010. It includes values for wood screws as well (I find sometimes it tough for the guys to swing hammers in some attics but they can get a mini impact driver and some 2 1/2" screws in there easily.

EngineeringEric,

Unless the latest edition of CSA086 has changed, nails may be used in double shear without clinching if they are alternately driven from each side.

jayrod,

The use of 2 1/2" screws sounds like a great idea for repairing trusses in place.

BA

Unless the latest edition of CSA086 has changed, nails may be used in double shear without clinching if they are alternately driven from each side.

jayrod,

The use of 2 1/2" screws sounds like a great idea for repairing trusses in place.

BA

@medeek,

'Structural Timber Design' by Abdy Kermani has a sample question on the design of a nailed-gusset eaves connection: can scan the relevant pages to you if you want. It details the nail spec and design of the ply gusset. butit's a UK book in SI units, and the 'K' factors will probably be different to those in US.

'Structural Timber Design' by Abdy Kermani has a sample question on the design of a nailed-gusset eaves connection: can scan the relevant pages to you if you want. It details the nail spec and design of the ply gusset. butit's a UK book in SI units, and the 'K' factors will probably be different to those in US.

- Thread starter

- #9

- Thread starter

- #10

EngineeringEric

Structural

A nice reference

SlideRuleEra

Structural

The USDA Forest Products Lab has performed long-term experiments on trusses using various connectors, including plywood gussets. See their publication "Longtime Performance of Trussed Rafters with Different Connection Systems"

![[idea] [idea] [idea]](/data/assets/smilies/idea.gif)

![[r2d2] [r2d2] [r2d2]](/data/assets/smilies/r2d2.gif)

![[idea] [idea] [idea]](/data/assets/smilies/idea.gif)

![[r2d2] [r2d2] [r2d2]](/data/assets/smilies/r2d2.gif)

- Thread starter

- #14

This is kind of what I have in mind however I have not yet determined the proper engineering/research to size the plywood gusset plates, number of nails and correct spacing and edge distances.

I will be using the ANSI TPI 1-2007 to size the members and matrix analysis to determine the moments, axial and shear forces, similar to what I've done here:

Link

I will be using the ANSI TPI 1-2007 to size the members and matrix analysis to determine the moments, axial and shear forces, similar to what I've done here:

Link

Ok, here's what I've normally done. Treat the whole thing as pinned (no moments at the joints). determined the member compression/tension. Then I figure out how many nails I need to transfer the largest members load at each joint. Then, by the time you fit all of those nails in using the allowable spacings as outlined by the CSA or NDS your plywood is sized for you.

- Thread starter

- #16

What do you consider the critical failure mode?

1.) Nails Shearing

2.) Nail pull out

3.) Plywood (tearing, crushing or shearing)

4.) Net section of the member

and would it be prudent to consider all of these failure modes.

Based on my previous research with MPC wood trusses I normally treat web members connecting to chords as pinned connections, however the peak joint, splice joint and the heel joint usually have some moment associated with them. The bottom chord splice joint shown in the diagram above is actually positioned so that it is very nearly at a zero moment along the bottom chord, this was done on purpose, hence only the tensile load is of any real concern. The peak joint can be modeled as rigid, semi-rigid or pinned, for simplicity I can go with pinned.

The main concern will be the heel joint since it is best to model this as rigid. The matrix analysis will give me the moment at this joint. I just need to figure out how to incorporate this additional load into the fastener loading.

1.) Nails Shearing

2.) Nail pull out

3.) Plywood (tearing, crushing or shearing)

4.) Net section of the member

and would it be prudent to consider all of these failure modes.

Based on my previous research with MPC wood trusses I normally treat web members connecting to chords as pinned connections, however the peak joint, splice joint and the heel joint usually have some moment associated with them. The bottom chord splice joint shown in the diagram above is actually positioned so that it is very nearly at a zero moment along the bottom chord, this was done on purpose, hence only the tensile load is of any real concern. The peak joint can be modeled as rigid, semi-rigid or pinned, for simplicity I can go with pinned.

The main concern will be the heel joint since it is best to model this as rigid. The matrix analysis will give me the moment at this joint. I just need to figure out how to incorporate this additional load into the fastener loading.

EngineeringEric

Structural

All of those things you listed, and some need to be checked. all are critical.

My process.

1) Find the load for all pin-pin, this is when all members are sized and checked

2) size the minimum size of plywood to take the load T/C with a pre-selected thickness (ie 15/32)

3) determine what my nail capacity is for pre selected nail (12d)

4) determine number of nails per 2x member

5) size check for plywood to handle all my nails

6) detail!

And some between the lines work is always required

My process.

1) Find the load for all pin-pin, this is when all members are sized and checked

2) size the minimum size of plywood to take the load T/C with a pre-selected thickness (ie 15/32)

3) determine what my nail capacity is for pre selected nail (12d)

4) determine number of nails per 2x member

5) size check for plywood to handle all my nails

6) detail!

And some between the lines work is always required

Rarely do I worry about nail pullout since in general the nails are clinched. Nail shear is the main concern but the maximum load for the nails take into account the plywood and base material they are being fastened into (At least in the Canadian Wood Design Manual).

To be honest, I rarely check the individual truss members unless the loading is changing. If they are only being used for their original design loading then I assume that they were sized appropriately to begin with.

To be honest, I rarely check the individual truss members unless the loading is changing. If they are only being used for their original design loading then I assume that they were sized appropriately to begin with.

- Status

- Not open for further replies.

Similar threads

- Question

- Replies

- 5

- Views

- 7K

- Replies

- 3

- Views

- 8K

- Replies

- 4

- Views

- 1K

- Locked

- Question

- Replies

- 4

- Views

- 711

- Question

- Replies

- 5

- Views

- 15K