I've done some work analyzing and programming a truss calculator for MPC wood trusses however I've put that project on hold and I'm not looking at trusses made with plywood gussets. I'm not finding a significant amount of information online regarding these types of trusses. Does anyone have any links or even books they could recommend. I would like to create a truss calculator for this type of truss that is similar to the previous calculator I started working on, however this time I will incorporate the wind and snow load cases as well as engineer the gusset plates (ring shank nails and glue).

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

Style variation

-

Congratulations MintJulep on being selected by the Eng-Tips community for having the most helpful posts in the forums last week. Way to Go!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Wood Gusset Connected Trusses

- Thread starter medeek

- Start date

- Status

- Not open for further replies.

About 40 years back, we did a lot of northern Hudson Bay stores in northern Canada with wood trusses... we used a Cremona diagram to analyze them by drafting and the connections used 1/2" D.Fir plywood gussets. The fasteners used were Stelco hardened spiral truss gusset nails (8ga x 2-1/2" long, I think). I seem to recall we used a capacity of 250 lb/nail, which was very high and they were driven from alternate sides.

CMHC used to have a manual and they had prescribed designs for roof trusses, also. I'll try to upload a file... having problems with it for some reason...

Dik

CMHC used to have a manual and they had prescribed designs for roof trusses, also. I'll try to upload a file... having problems with it for some reason...

Dik

File... problem... 20 meg file...

Dik

Dik

- Thread starter

- #23

It seems like the Canadians have done a lot more with wood gussets than their neighbors to the south. I'm trying to determine the specs on the special hardened spiraal concrete nails that were used on these plans.

Another point of confusion for me after some further study of the NDS is with plywood. The NDS rates the strength of plywood not by its thickness but rather by the number of plies and by the span rating. What I would like to know is DF EXP1 STRUCTURAL 1 15/32 or 1/2 readily available and can I get it in 5 ply with a span rating of 32/16 or 24/0?

Another point of confusion for me after some further study of the NDS is with plywood. The NDS rates the strength of plywood not by its thickness but rather by the number of plies and by the span rating. What I would like to know is DF EXP1 STRUCTURAL 1 15/32 or 1/2 readily available and can I get it in 5 ply with a span rating of 32/16 or 24/0?

- Thread starter

- #24

After doing my requisite homework (remember I am still quite new to the structural field) I've determined that for double shear I have 4 yield limit equations for the fastener checks at each joint. I'm some previous posts I've seen comments about assigning a certain lateral force per fastener, this seems a whole lot simpler than running a bunch of calculations. Where did these simpler allowable load per nail come from?

- Thread starter

- #26

After running a few numbers for 10d nails into 15/32 DF Structural 1 plywood (5 ply) with DF truss members it looks like the 10d nails don't have as much capacity as I originally thought. In particular I'm looking at the splice joint in the bottom chord with a pure tensile load of approx. 1800 lbs. It looks like I'll need at least 10 nails on each side in double shear. However the plywood itself is the weak link, 3-1/2 deep gusset on each side of the bottom chord will not be enough for this tensile load. The load is D + S so my Cd is 1.15, which buys me a little but not much.

Not sure what you mean by a 10d nail. The diameter seems to be different depending on which chart you look at. On the attached chart, the diameter is 0.148" and the length is 3". Is that what you are using? If so, you will be clinching the nails.

Are you using DF truss members? In my area, SPF is more common and much easier to work with for nailing.

It is not necessary for the gusset plate to be 3.5" deep. Make it deeper if required for the sloping chord member.

BA

Are you using DF truss members? In my area, SPF is more common and much easier to work with for nailing.

It is not necessary for the gusset plate to be 3.5" deep. Make it deeper if required for the sloping chord member.

BA

Check publications from University of Virginia. They are big on this stuff. I built my first house and many garages with the system you are looking at, but I always used ring shank nails, With the modern nail guns you can add plenty more than your numbers call for to be sure. Clinching not needed and most nails won't go much beyond the 2 inch members. Thus, call that extra length as added, not computed for , strength.

Using 1/2" plywood gussets, the overall width of two gussets and a 1 1/2" member is 2 1/2". According to our code, you can use 2 1/2" nails in double shear provided that nails are alternately driven from each side. Alternatively, you can use 3" nails driven from either side and clinched. Nail capacities and minimum spacing are stipulated in our code and presumably also in other timber codes.

BA

BA

@ medeek,

This book -

has design details for plywood eaves gusset on pp 204-208, but in SI units to a BS code, so you would need to do some converting. Principles will be the same, though.

This book -

has design details for plywood eaves gusset on pp 204-208, but in SI units to a BS code, so you would need to do some converting. Principles will be the same, though.

- Thread starter

- #31

I think I've figure it out but we will see. I'm working on the code right now to calculate everything. I'll be using the AWC NDS 2012 and the ANSI TPI 1-2007 where applicable. Once I get something together I'll post it and let everyone take a look at it. My hope is that it will help take some of the guess work out of designing wood gusset connected trusses, not just for myself, but others as well.

woodman88

Structural

- Oct 23, 2009

- 1,020

Here is a fairly good articles on plywood/OSB gussets for 2x wood trusses. As for the size of nails I prefer to use 8d (or 6d) common nails from each face, with 1/2 gussets. The 8d will penetrate both gussets which I feel will add strength if from each face similar to clinching. Of course you can not use the double value for the calculations. Adding glue to the high stress members like BAretired stated also helps.

Garth Dreger PE - AZ Phoenix area

As EOR's we should take the responsibility to design our structures to support the components we allow in our design per that industry standards.

Garth Dreger PE - AZ Phoenix area

As EOR's we should take the responsibility to design our structures to support the components we allow in our design per that industry standards.

- Thread starter

- #33

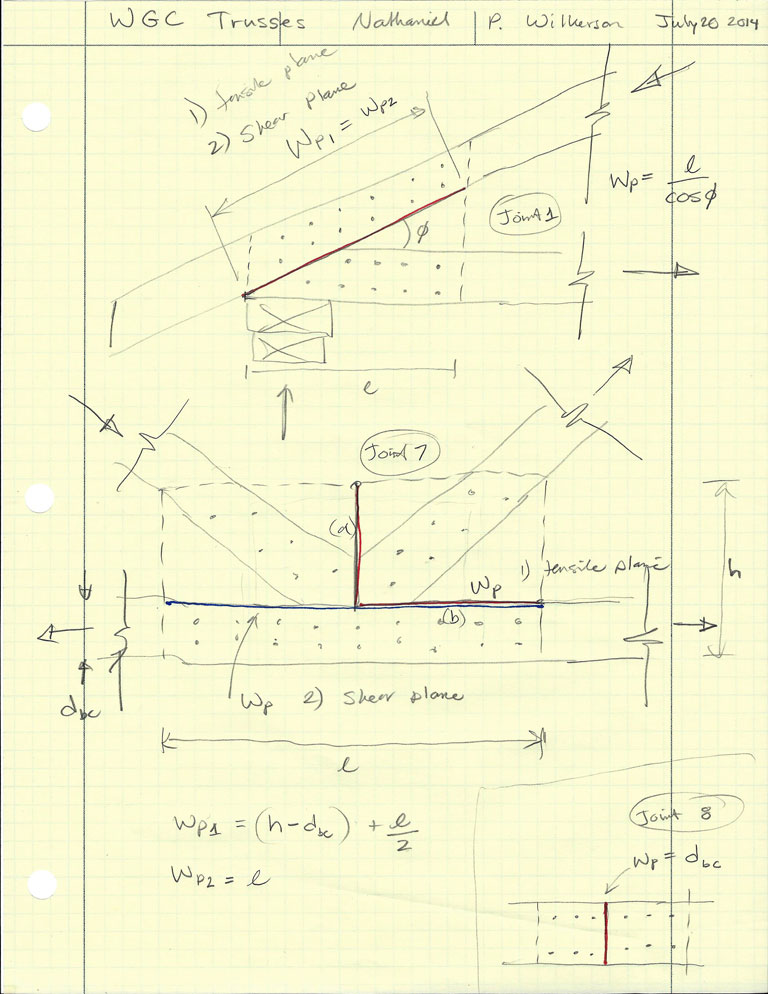

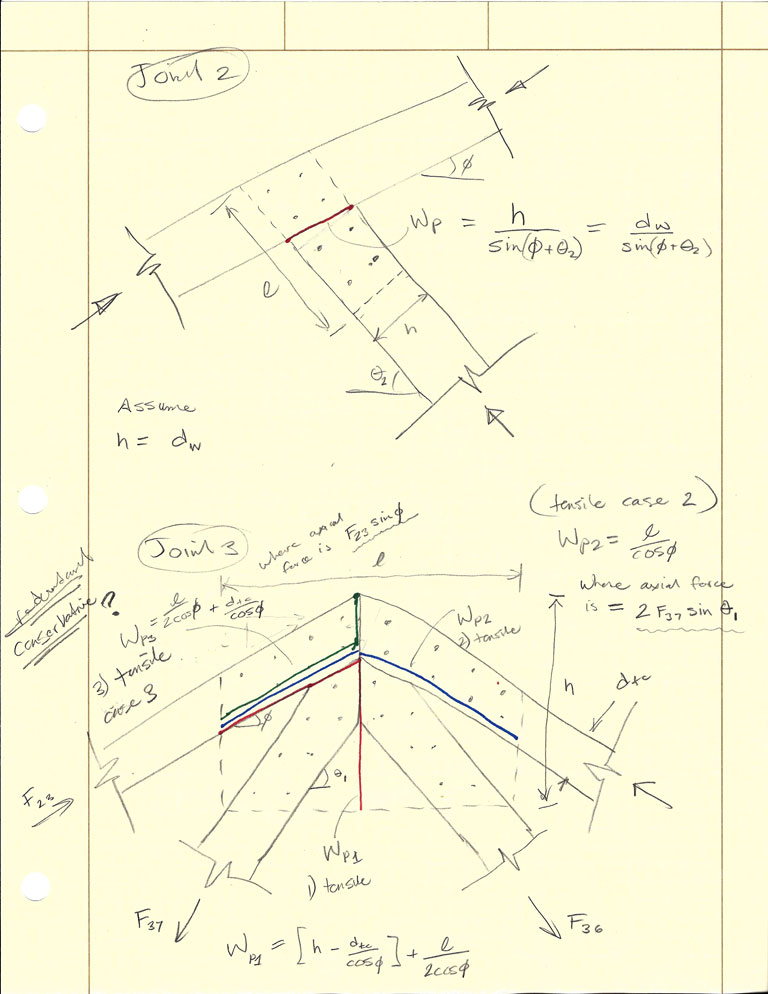

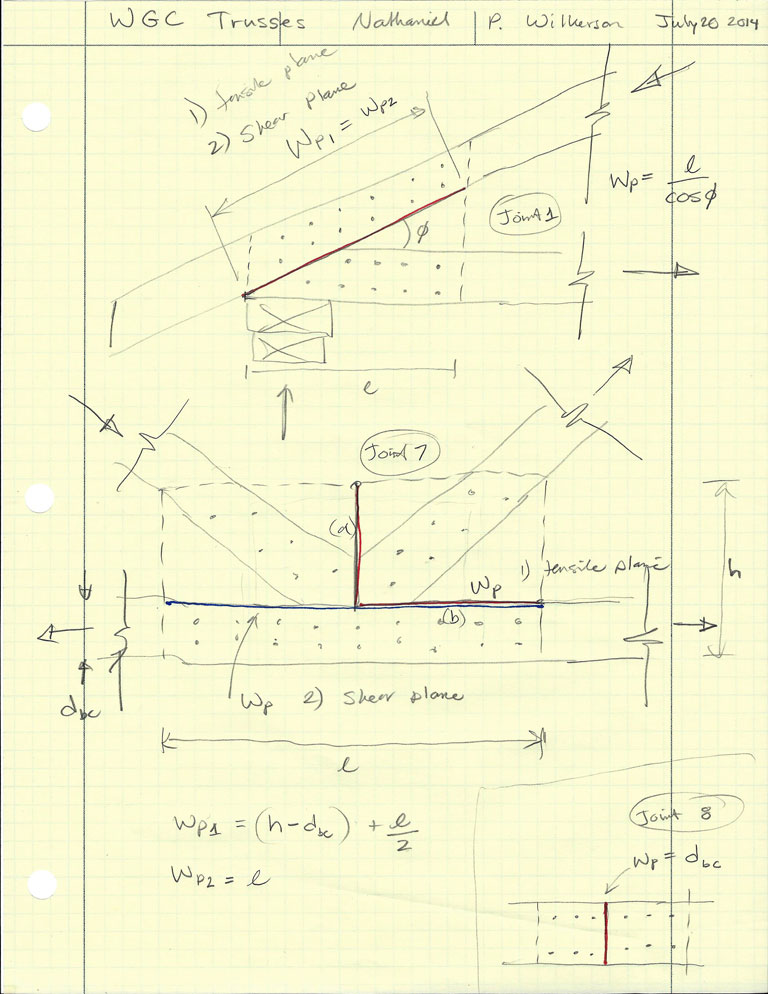

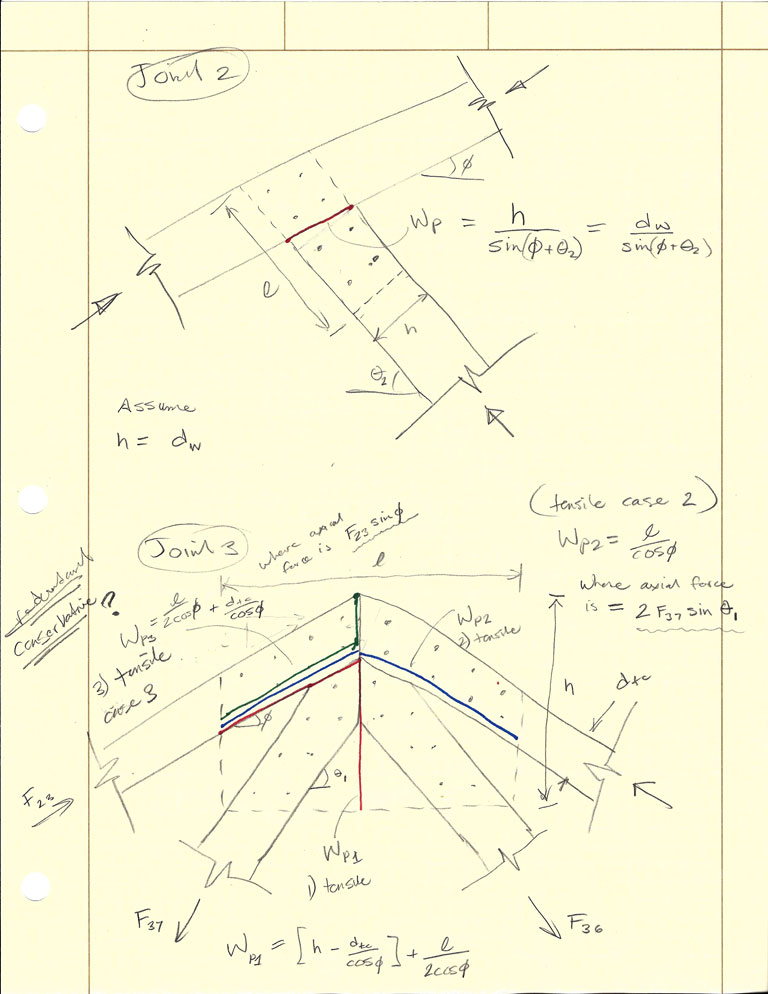

Now that I think I have the fastener portion figured out I'm now looking at the failure modes of the plywood gusset plates themselves in tension and in shear. ANSI TPI 1-2007 describes the critical dimension as the gross width of the plate measured parallel to the joint line (section 8.4.3 and 8.5.3). What I've drawn below are these gross widths for tension and shear for each joint.

I am trying to consider all failure modes. In particular Joint (3) has possibly 3 failure modes but tensile case 2 and tensile case 3 may be redundant.

I am trying to consider all failure modes. In particular Joint (3) has possibly 3 failure modes but tensile case 2 and tensile case 3 may be redundant.

- Thread starter

- #38

You are correct manstrom. The engineering costs for a one off of this type of truss is too high forcing most ranchers, farmers and DIY'ers to just wing it and forgo the engineering. I'm trying to create a program that automates the engineering of this type of truss so that it is affordable to do the engineering. I do have some experience with MPC trusses and I have done this sort of thing before, look at:

Medeek Truss Designer

However, I've never looked at plywood gusset plates before so I'm in uncharted territory.

Last night I spent some time rereading certain sections of the ANSI TPI 1-2007 and I now think I have a rational approach for dealing with the additional lateral forces on the fasteners due to moments at the peak joint and splice joints.

Medeek Truss Designer

However, I've never looked at plywood gusset plates before so I'm in uncharted territory.

Last night I spent some time rereading certain sections of the ANSI TPI 1-2007 and I now think I have a rational approach for dealing with the additional lateral forces on the fasteners due to moments at the peak joint and splice joints.

- Thread starter

- #39

Sorry the link above should have been:

Medeek Truss Designer

To help get this project off the ground I'm listing it at Kickstarter (anyone had any experience with them doing a similar thing?).

Kickstarter Project

I've had some of my engineering friends baulk at this approach to engineering however I think more and more automation of engineering through software is the future of this profession. Most practicing engineers are already half way there since we all use Excel spreadsheets for most of our mundane and typical calculations. I'm just trying to take it a few steps further as it relates to wood gusset connected trusses.

Medeek Truss Designer

To help get this project off the ground I'm listing it at Kickstarter (anyone had any experience with them doing a similar thing?).

Kickstarter Project

I've had some of my engineering friends baulk at this approach to engineering however I think more and more automation of engineering through software is the future of this profession. Most practicing engineers are already half way there since we all use Excel spreadsheets for most of our mundane and typical calculations. I'm just trying to take it a few steps further as it relates to wood gusset connected trusses.

woodman88

Structural

- Oct 23, 2009

- 1,020

Why not just add plywood gussets to your program (with some CYA notes) with the plywood tension/shear and nails holding values per a psi of plywood? After all an engineer should be reviewing and sealing any engineered design.

Garth Dreger PE - AZ Phoenix area

As EOR's we should take the responsibility to design our structures to support the components we allow in our design per that industry standards.

Garth Dreger PE - AZ Phoenix area

As EOR's we should take the responsibility to design our structures to support the components we allow in our design per that industry standards.

- Status

- Not open for further replies.

Similar threads

- Question

- Replies

- 5

- Views

- 7K

- Replies

- 3

- Views

- 8K

- Replies

- 4

- Views

- 1K

- Locked

- Question

- Replies

- 4

- Views

- 735

- Replies

- 2

- Views

- 4K