craigclick

Industrial

- Dec 5, 2010

- 10

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Thanks for the input. I'll clarify:

1. I thought the nomenclature PTR was universal, but I guess it only applies to Mexico. In this case, it is square tube, A36 steel, with a wall of 1/8". In this size, 2"x2". A thicker wall is not available.

2. The FLD HD screws, 28 TPI, are to keep a clean visual look. The wall is tapped.These are supports for shelves in a high-end residential installation.

3. I have placed the screws above center. Perhaps I should place them higher, closer to the angle.

4. A backing plate inside the square tube is not possible, nor is it possible to place nuts. If you thought it essential, I could place nut-serts to support more thread length, but then I would have to remove material from the aluminum angle, so that they would not stand/off (proud) from the post 1/16". In which case, I would probably consider usine 1/4" thick angle.

3. The shelves are 10' long, and have an internal structure of steel to keep them from sagging under the weight of books. Total weight of shelf, filled with books is apprximately 330 lbs.

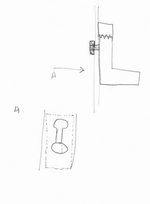

4. I've attached another drawing that shows how the shelves are mounted. There will be two angle supports in front off the posts. There will be five anglem supports off the rear wall, each 4" long.

Thanks all for your comments; it's appreciated.

Thanks for taking the time to respond. The gap is a design element from the architect. The reason I started this post is precisely because of your comment that the 'moment' changes the force from shear, and I wanted to know if it could be calculated. My original idea was to use a T profile with four screws, but I thought perhaps it was overkill, and the architect didn't like it as she wanted a cleaner look. Your comment made me think of another approach; a horizontal slot with a Z bracket. Thanks for your comments.SO if I understand this right, the strange 2" posts are in the outer corner of this bookshelf thing with a very stiff shelf if it's not going to visibly bend with some 150kg of books on it?

My issue would be why the gap between the edge of the shelf and the frame of the post?

Hoving a moment on the angel barcket just increases the pull out force considereably. Having the shelf flush with the surface of te post makes the screws basically in shear where they will be very strong, but having the shelf shy will lead to very high forces on the screws and risk of pull out.

I doubt you can calculate this to any degree of accuracy as so much depends on the exact diameter of the hole and the strength of the screw to create a thread in the steel? 3mm thick isn't a lot of thread and over tighten it once and your hole is buggered.

Think you would be much better off with an oval type hole or rectangular vertical slot and an angle bracket which has a reverse angle on the inside.

Like this. https://www.ironmongerydirect.co.uk...bh73-ijH0I935TwYbyduR3TjSG1uCK1hoC98UQAvD_BwE

I think you can get a very simple and clean block machined with a T shaped pin or pins on the reverse which then slot into keyhole shaped slots in the frame. Very strong and would look "magic" as there is no visible means of fixing.Thanks for taking the time to respond. The gap is a design element from the architect. The reason I started this post is precisely because of your comment that the 'moment' changes the force from shear, and I wanted to know if it could be calculated. My original idea was to use a T profile with four screws, but I thought perhaps it was overkill, and the architect didn't like it as she wanted a cleaner look. Your comment made me think of another approach; a horizontal slot with a Z bracket. Thanks for your comments.