Gaganaut06

Aerospace

- May 2, 2023

- 21

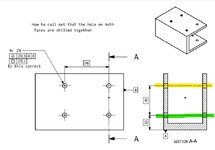

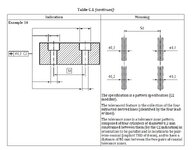

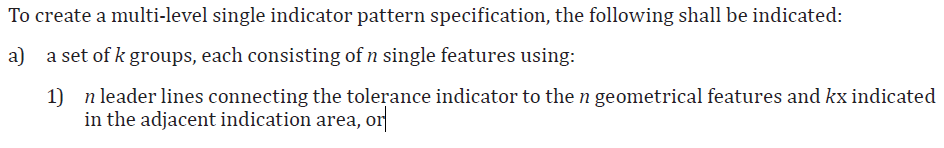

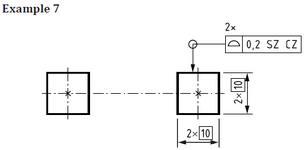

I am having a pattern of two concentric holes on both the faces of a C channel, these holes are drilled together in one go. The pattern has four sets of these two holes ( total 4x2=8 ). How to properly show this in drawing. I am using iso - gps