EngDM

Structural

- Aug 10, 2021

- 694

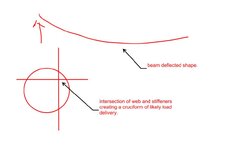

I've been doing a little digging to see if cap plates are strictly required to pick up W beams bearing on an HSS (round or square) but haven't been able to come to a clear cut concensus. For a rock socketed round HSS at this site the refusal depths are all over the place, and the site is in such a remote place, that we want to make this as simple to construct as possible. My immediate thought was to just weld to the underside of our steel beam floor, which avoids any cap plate welding (so effectively eliminating half of the welding), but I can't seem to find any information saying NOT to do this. As long as the beam has been checked for web crippling, which we have added stiffeners for, is there any other considerations? All lateral loads are transfered to battered piles elsewhere along the perimeter, so for all intents and purposes this is a strictly axial/bearing condition.

FYI - connection has to be a welded connection, otherwise any bolt holes in the beam flange would need to be site drilled which for obvious reasons we would rather not do.

FYI - connection has to be a welded connection, otherwise any bolt holes in the beam flange would need to be site drilled which for obvious reasons we would rather not do.