JStructsteel

Structural

- Aug 22, 2002

- 1,438

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Its about a 100 year old building, so seen its share of loading.I’d base my decision on two major factors:

(A) Project Fee: If your fee is healthy then you probably should redesign since that would be in most agreement with what one ought to ethically do. If it’s a light fee, then I would tend towards replacement in kind with the caveat of B.

(B) Loading History: I would only replace it in kind given a low fee if the roof had seen a design level event. If the area has never had snow / wind / whatever near modern design levels, I would not just replace in kind regardless of fee. In that case we cannot possibly know just by the fact that it stood for this long how it would perform during such events.

In general, I’m a big fan of load testing, and if it passed muster during a design event, I would trust that more than I would trying to analyze it using our simplified methods / tools. But if not, then a redesign (or at least reanalysis) it is.

This will be a livable space, so trusses not an option. There are some interior walls I can use as bearing, so that will help.I do a huge amount of remediation and disaster work. Assuming its possible in your area I highly recommend replacing the roof with a truss system. It will likely lead to needing to do some footing extensions where the girder trusses are but you get a far more predictable and reliable diaphragm long term. In my area its also 20-30% cheaper than a hand framed system that meets code requirements.

No. No, NO. NO. All caps 968 point font size NO. It's most certainly not. You simply cannot make that statement***. MAYBE what they have works.Obviously what they have works,

Maybe you don't mean it that way, but LOOK at what you WROTE.I’d base my decision on two major factors:

(A) Project Fee: If your fee is healthy then you probably should redesign since that would be in most agreement with what one ought to ethically do. If it’s a light fee, then I would tend towards replacement in kind with the caveat of B.

Now that I'm done with my little broadside at enable, I can agree with the following:I usually design roof framing with obvious load paths, as opposed to what's shown here.

This. But at the residential scale it's simply not practical (I think Algo center did load testing on their parking deck, for a large area).In general, I’m a big fan of load testing, and if it passed muster during a design event, I would trust that more than I would trying to analyze it using our simplified methods / tools. But if not, then a redesign (or at least reanalysis) it is.

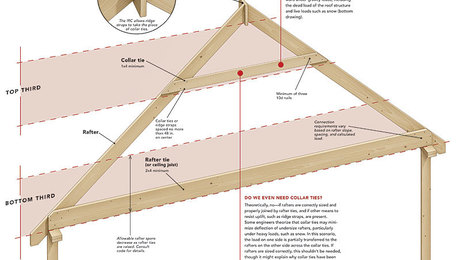

This is a small roof. If the attic is livable space, the roof slope is probably pretty steep. I imaging the thrust loads aren't Earth shattering in their magnitude.

When I do it I will typically use ridge and hip beams to support the rafters. At the ridge/hip connection I king post down to a bottom chord beam. If I can ill try to get 1 or 2 interior load points for the bottom chord to keep the size realistic and avoid exterior footing extensions (easier to put them in the crawl if possible). For connections I will use off the shelf Simpson connectors or 5/8" to 3/4" all thread thru bolt connections. I'll also use both in combinations. I will use ceiling joists as ties where possible.@ lexpatrie & PlinkoEng,

Not an old timer here, and not looking for a fight or dramatics.

Just trying to get some advice on the best way to handle this roof re-frame w/o it being trussed.

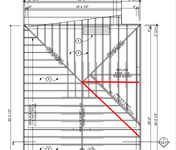

This is an existing roof, being replaced. They want to keep the same basic framing and space inside, thus limited places for posts. At the top of the page, no place. At the bottom at the end of the ridge board, I can post down, and also change the hip on bottom left to a gable.When I do it I will typically use ridge and hip beams to support the rafters. At the ridge/hip connection I king post down to a bottom chord beam. If I can ill try to get 1 or 2 interior load points for the bottom chord to keep the size realistic and avoid exterior footing extensions (easier to put them in the crawl if possible). For connections I will use off the shelf Simpson connectors or 5/8" to 3/4" all thread thru bolt connections. I'll also use both in combinations. I will use ceiling joists as ties where possible.

It's a pretty overkill solution but it's easy to prove and I know it won't fail. Easy enough to also build in the floor system once you have a predictable roof system. Typically I do all that work, customer doesn't like the cost and then goes back to trusses like I suggested at the start. Attic trusses can also be used for the living space.

I would definitely agree with that simplification of geometry. I would also tell the client it gets them more height and useable width in the dormer. Value engineering is a sweet sweet phrase.This is an existing roof, being replaced. They want to keep the same basic framing and space inside, thus limited places for posts. At the top of the page, no place. At the bottom at the end of the ridge board, I can post down, and also change the hip on bottom left to a gable.

So that hopefully simplifies the framing, the dormer on the top right complicates the load path for the hip beams, they have to carry the additional load from the valley of the dormer.

Its almost like I want to move the valley beam from the top dormer to be opposite and in line with the left hip beam.

View attachment 875

We had a guy around here like that. I have made a lot of money fixing his errors. Fortunately he has retired.@lexpatrie - Thanks for that post. I feel the same and have had some fights with old timers in my area over these concepts. Felt too new to have a rant but you nailed it.

I've had a senior engineer in my area say that vaulted rafters to a ridge board with NO TIES was acceptable because the wall acts as a beam once it's sheathed and the perpendicular interior walls tie to the exterior walls to prevent them from pushing out. After some shocked silent thinking I asked if he would control the interior to exterior wall joint and have it be verified. He responded that wasn't necessary because there are millions of roofs like that in the world. This was a 2nd floor roof.

The exterior walls were 6 degrees out of plumb and the ceiling and wall sheet rock was cracked all over the place. Customer accepted his solution due to cost of adding engineered ties. Snow load at the property is 35 PSF, I was reviewing it in the summer.

I dropped a note to building safety but they said the other guy stamped it so it's all good.