noobokgbp

Mechanical

- Jul 10, 2024

- 8

Hello All,

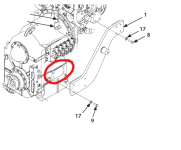

I am working on designing a threaded insert for a transmission casing where the original mounting hole threads were stripped. The casing material is ductile iron (6545-12), and the original damaged threaded blind hole has an M16x2mm thread, so the inner diameter of the insert must match this specification.

Since this is my first time designing a threaded insert, I'm unsure where to begin with the calculations and would appreciate any guidance. The only load case i am considering on the bolt threading into the insert will be from the transmission's weight and the specified torque for the bolt, which is 216 Nm. Is this correct? The transmission is side mounted, so the bolts are loaded in shear between the bracket and transmission.

Any help or advice would be greatly appreciated.

I am working on designing a threaded insert for a transmission casing where the original mounting hole threads were stripped. The casing material is ductile iron (6545-12), and the original damaged threaded blind hole has an M16x2mm thread, so the inner diameter of the insert must match this specification.

Since this is my first time designing a threaded insert, I'm unsure where to begin with the calculations and would appreciate any guidance. The only load case i am considering on the bolt threading into the insert will be from the transmission's weight and the specified torque for the bolt, which is 216 Nm. Is this correct? The transmission is side mounted, so the bolts are loaded in shear between the bracket and transmission.

Any help or advice would be greatly appreciated.

Last edited: