the original hellbilly

Agricultural

- Nov 7, 2024

- 3

Hi all,

New member here looking for some help with a job I have for a customer.

I have had a chat with a local pig farmer. He has a biodigester on his farm that processes the effluent from his piggery.

Currently he is just flaring the gas to get rid of it, he would like to make use of the heat instead of wasting it.

He is feeding his pigs a porridge of grain and minerals that is watered down to the point where it can then be pumped around his sheds to feed troughs. We have discussed heating the water so that on cold days the pigs won't have near frozen porridge, this will help increase yield as the pigs won't be using body heat to warm their food.

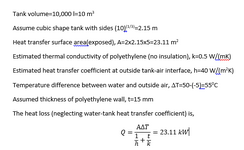

I plan to build a stainless steel heat exchanger that is connected to a 10 000 l polyethylene water tank by a closed loop. This will use the gas to heat water and convection currents will circulate water into and out of the tank.

I am trying to figure out the math's for this system. I want to know what sort of temperature increase we can expect over a 24 hour period, taking into account the heat losses that will be constantly occurring.

Some stats are listed below:

Biogas generated in 24 hours: 210 cubic metres

Ambient air temperature: -5 degrees C at night in winter to +30 degrees C in summer

Water temperature before heating: 10-20 degrees C

Every 24 hour period will see the 10 000l tank completely used and refilled

If any one can provide me some advice on how to work this out, that would be much appreciated. If I left any details out please let me know.

New member here looking for some help with a job I have for a customer.

I have had a chat with a local pig farmer. He has a biodigester on his farm that processes the effluent from his piggery.

Currently he is just flaring the gas to get rid of it, he would like to make use of the heat instead of wasting it.

He is feeding his pigs a porridge of grain and minerals that is watered down to the point where it can then be pumped around his sheds to feed troughs. We have discussed heating the water so that on cold days the pigs won't have near frozen porridge, this will help increase yield as the pigs won't be using body heat to warm their food.

I plan to build a stainless steel heat exchanger that is connected to a 10 000 l polyethylene water tank by a closed loop. This will use the gas to heat water and convection currents will circulate water into and out of the tank.

I am trying to figure out the math's for this system. I want to know what sort of temperature increase we can expect over a 24 hour period, taking into account the heat losses that will be constantly occurring.

Some stats are listed below:

Biogas generated in 24 hours: 210 cubic metres

Ambient air temperature: -5 degrees C at night in winter to +30 degrees C in summer

Water temperature before heating: 10-20 degrees C

Every 24 hour period will see the 10 000l tank completely used and refilled

If any one can provide me some advice on how to work this out, that would be much appreciated. If I left any details out please let me know.