shvet

Petroleum

- Aug 14, 2015

- 747

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Hi,

This is not going to work; you will carry forward light phase with heavy phase.

You must disconnect the light phase pipe.

Pierre

Not when there is no inflow it isn't.Little inch,

it is very clear ! this is a LL separator.

bottom valve is closed , open only to drain the separator.

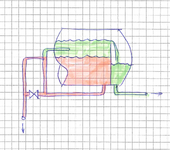

Green is light phase , red is heavy phase .

The interface is controlled by the height of the inverse U pipe .

Pierre

Shvet.

Block the light line, no connection to the vapor space.

A description and explanation are given in Perry's chemical Engineer's handbook - page 15-26 -7th edition

A schematic with equation.

In your case ZL is the height of the weir .

What is the L-L coalescer used in the 2nd diagram - a knit wire mesh pad or a tilted cross flow plate pack or some other?