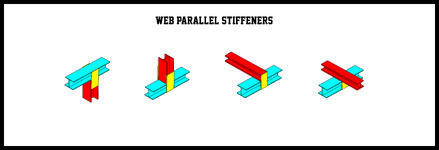

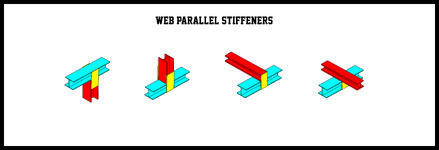

Adding transverse stiffeners perpendicular to a web

(I beams and columns) stiffen the web against out

of plane deformations. What about adding only

transverse stiffeners parallel to the web? It’s a one

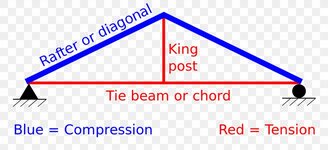

storey project involving 6м span, RC columns, simple

steel king post roof truss (not tied king post) consisting

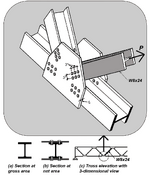

of HEA profile. Local steel contractor is …. I want to

approach this project differently. Simple, easy to

fabricate and reliable steel connections. What do you

think, is it feasible to satisfy AISC, EC3?

(I beams and columns) stiffen the web against out

of plane deformations. What about adding only

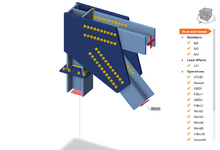

transverse stiffeners parallel to the web? It’s a one

storey project involving 6м span, RC columns, simple

steel king post roof truss (not tied king post) consisting

of HEA profile. Local steel contractor is …. I want to

approach this project differently. Simple, easy to

fabricate and reliable steel connections. What do you

think, is it feasible to satisfy AISC, EC3?